Plain Beam Trolleys

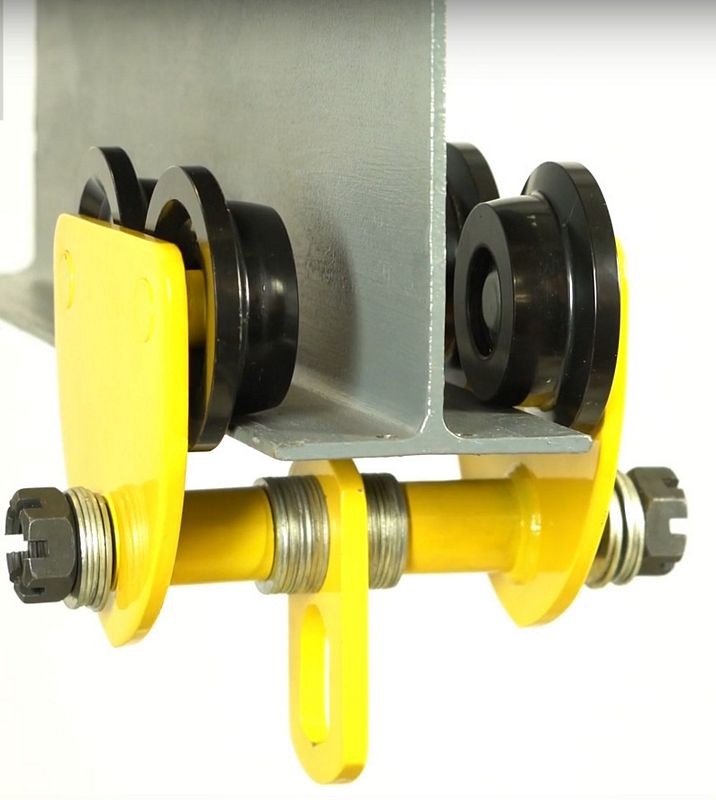

Plain Beam Trolleys are designed to freely traverse the length of the beam flange it is attached to. It gives flexibility to the operator and allows the load to be easily moved from one place to the other with ease.

Installation of Plain Beam and Geared Beam Trolleys

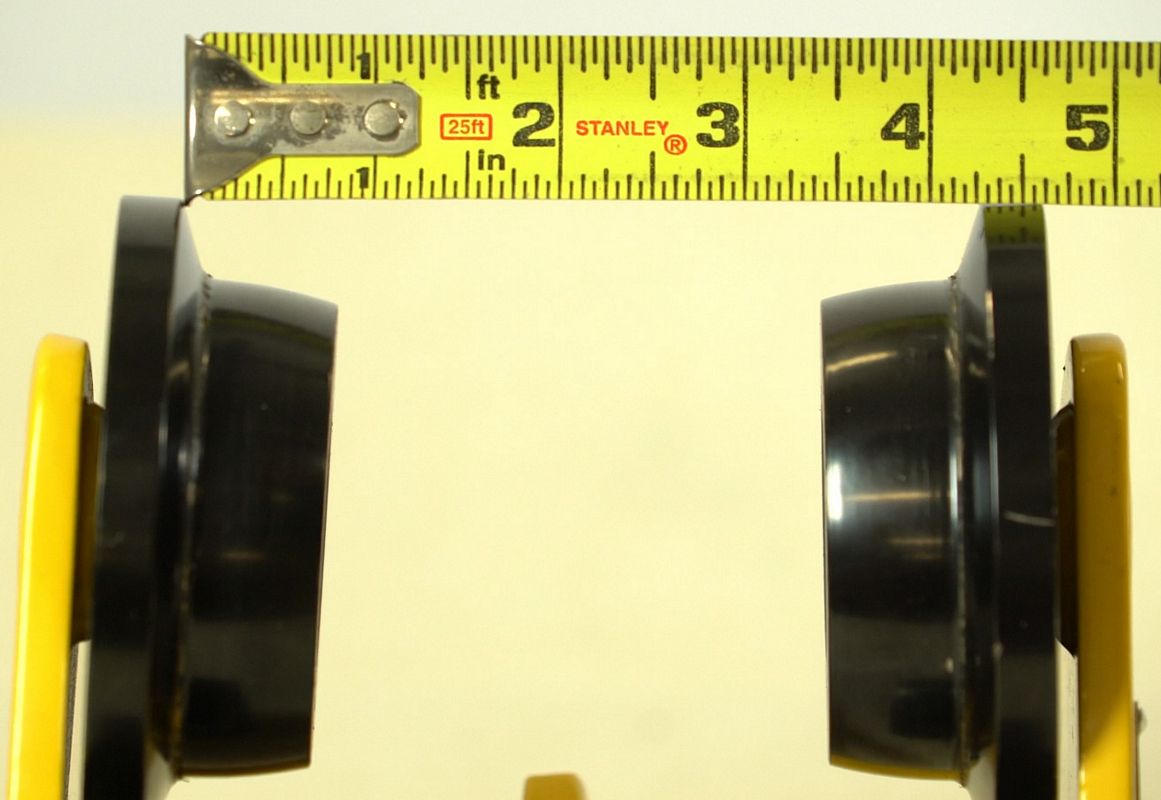

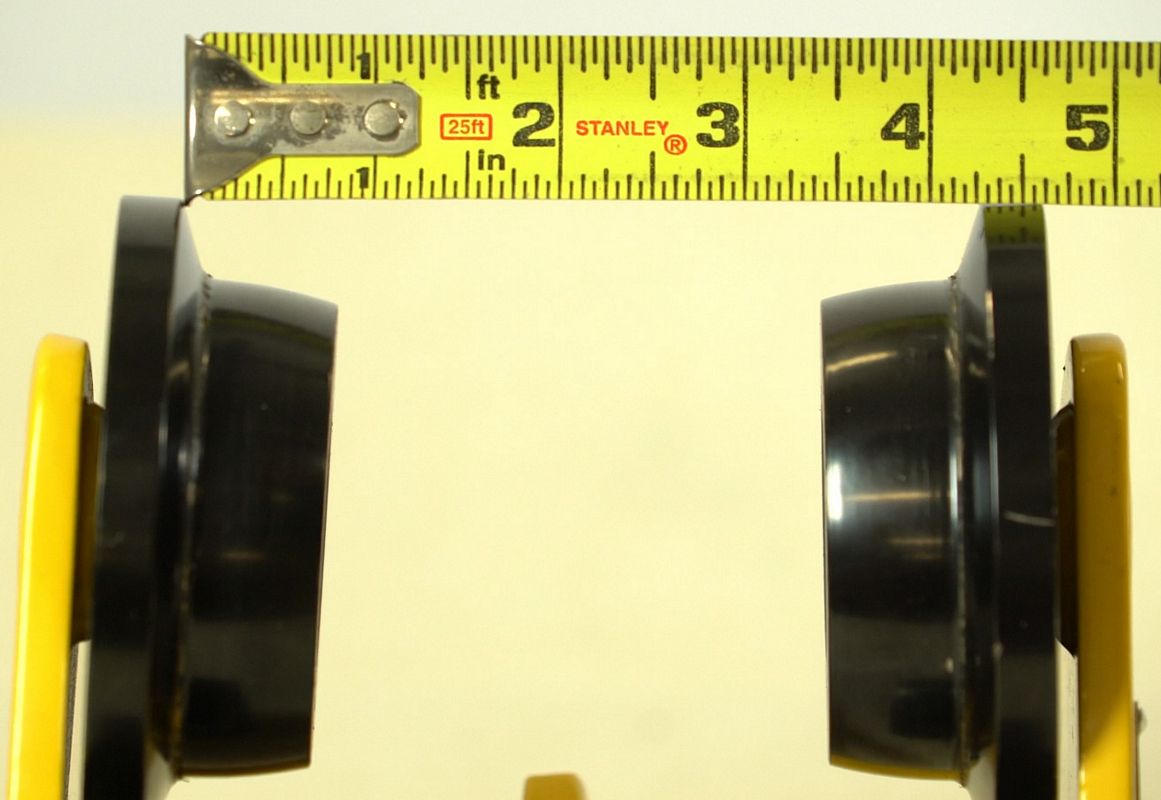

Measure the width of the runway beam.

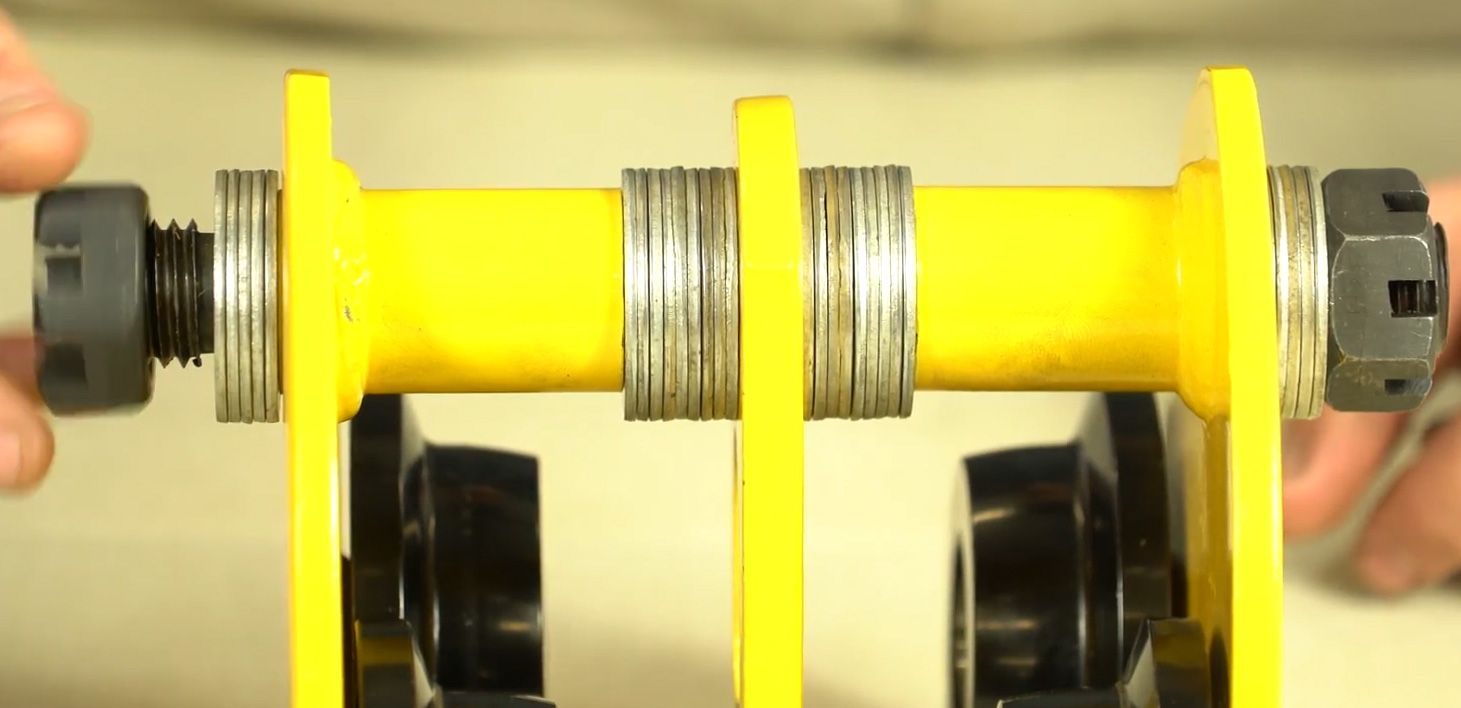

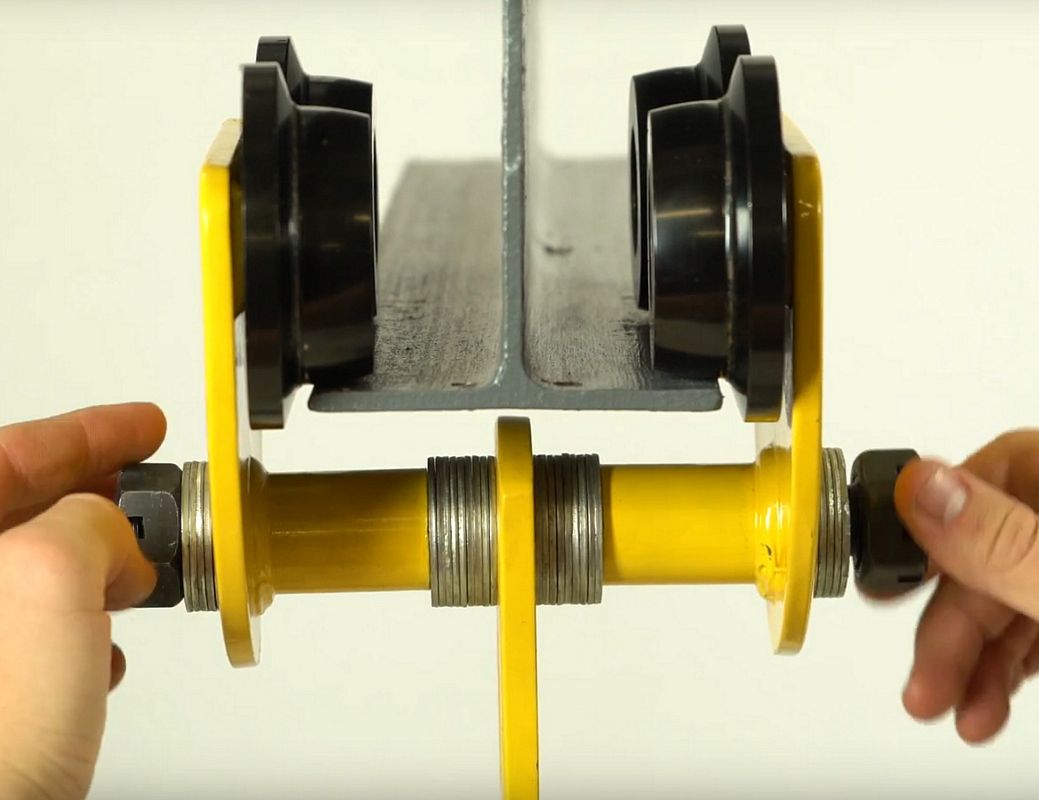

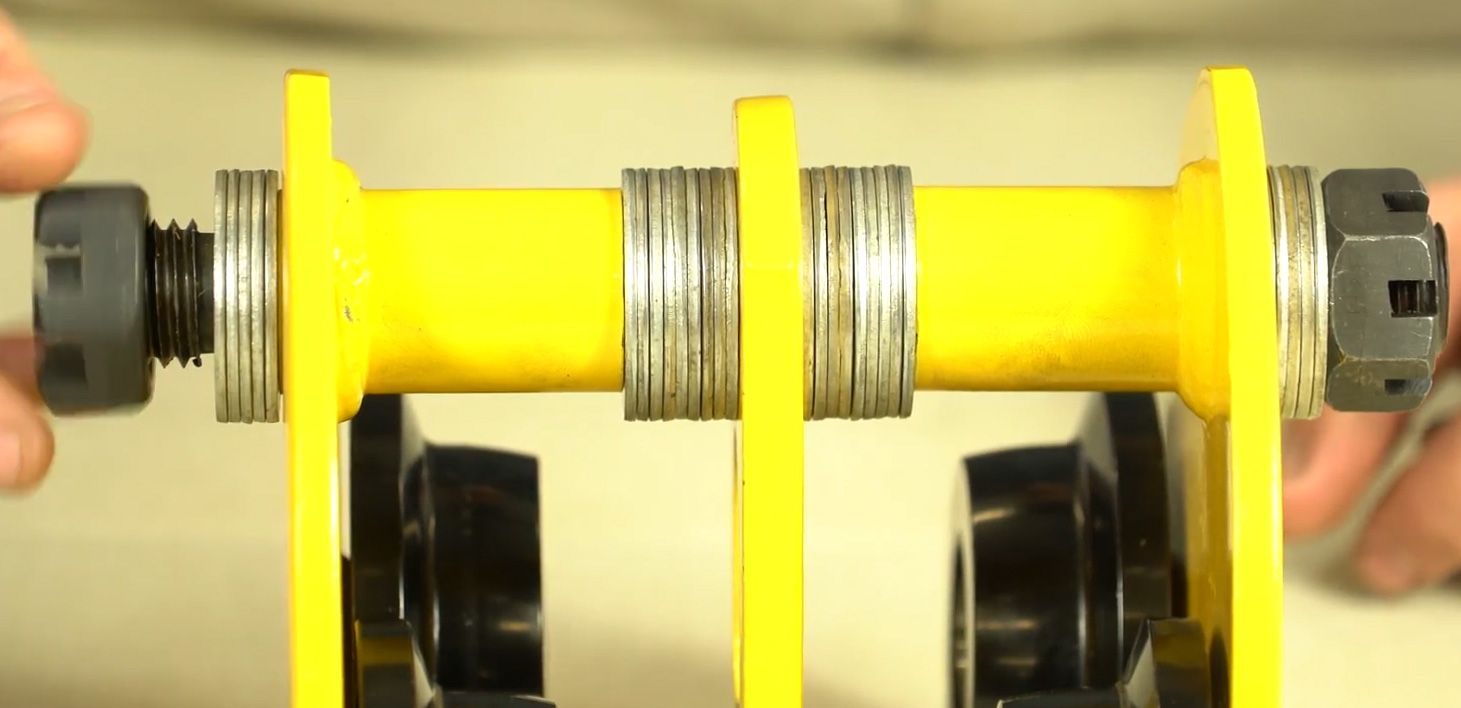

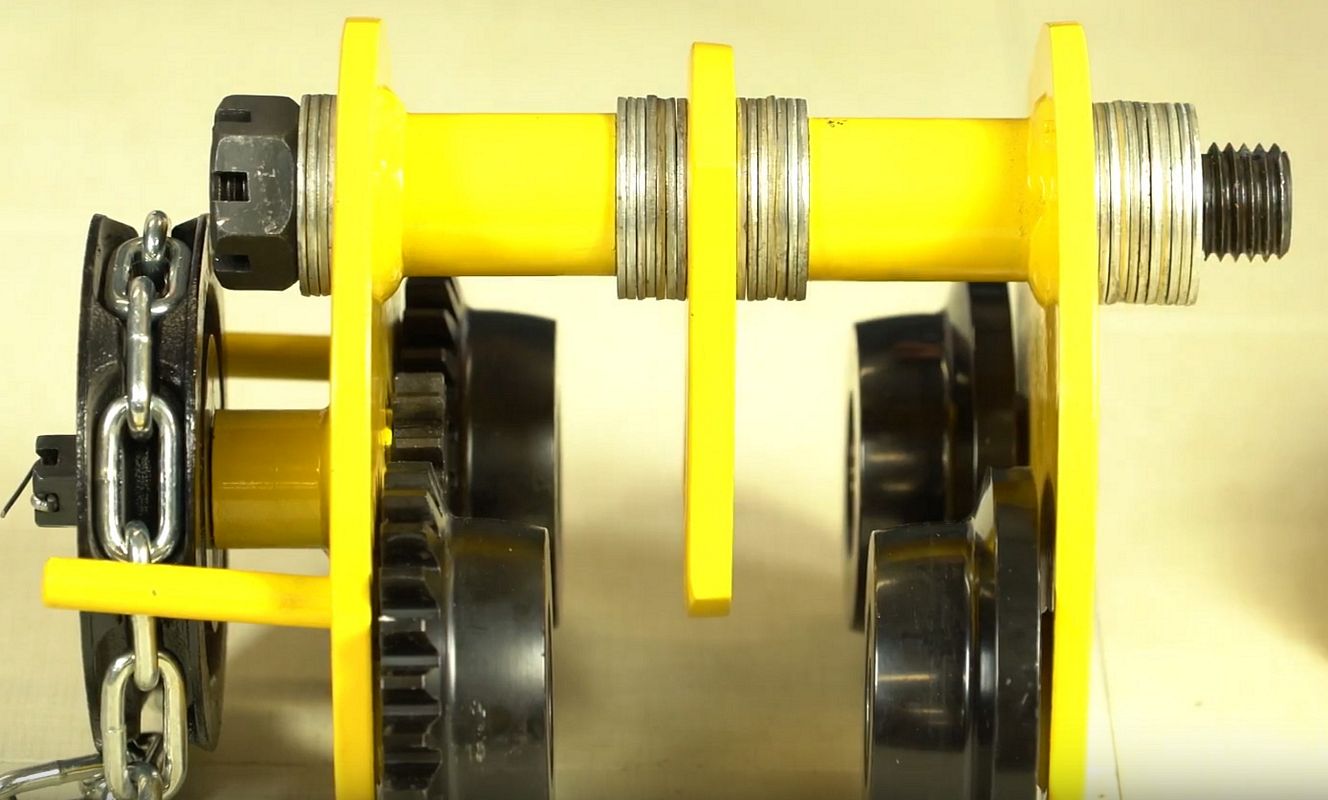

Assemble the suspension plate and required number of spacer washers to the inside of the trolley side plates.

The dimension between the trolley wheel flanges should be ¼” larger than the beam flange.

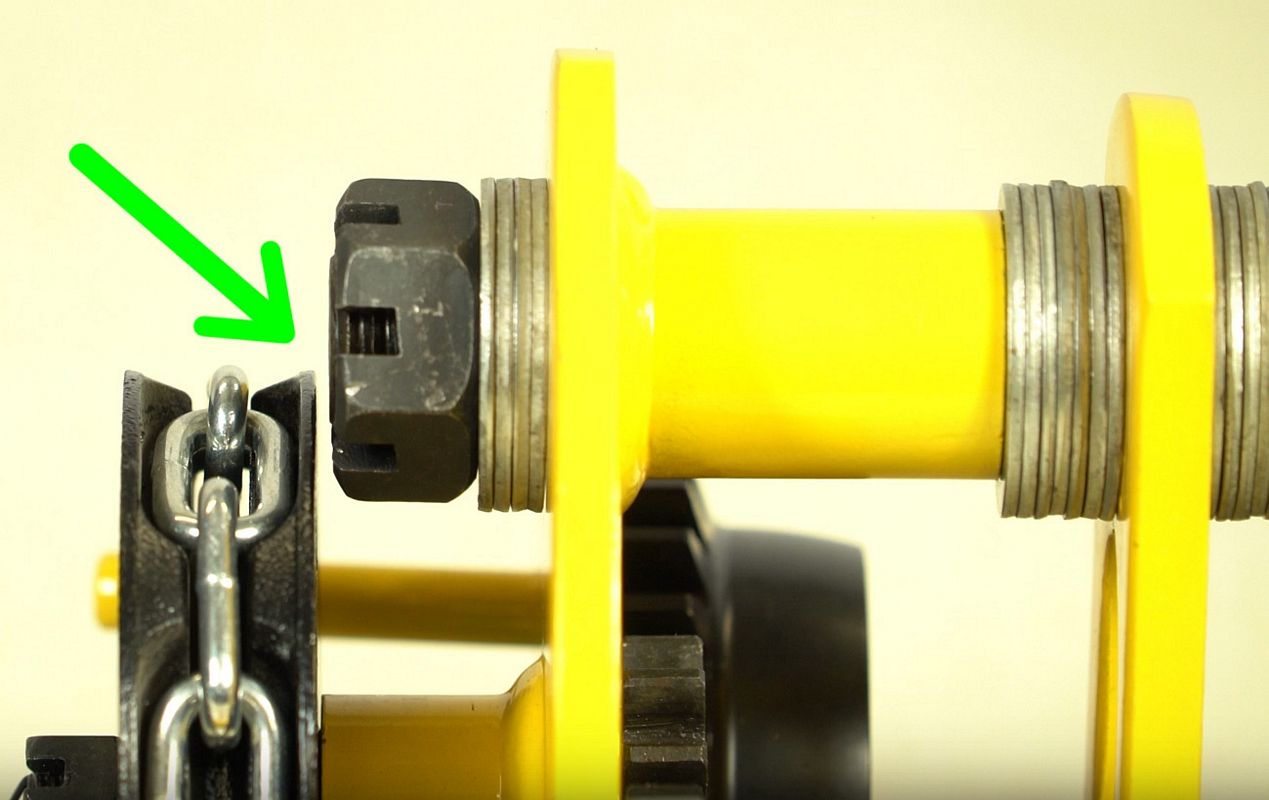

Assemble the remaining washers to either side of the trolley side plates, and fit the nuts to the hanger pin.

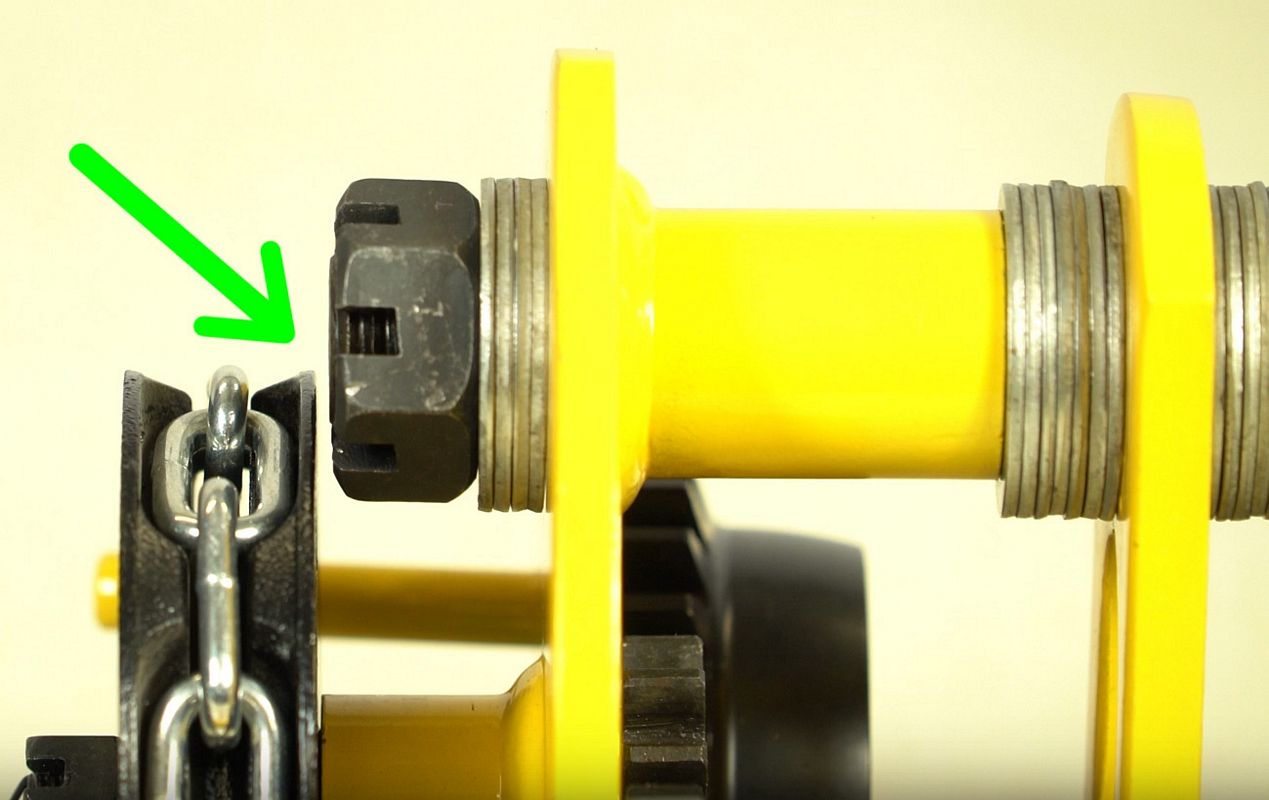

It is important to note that for geared beam trolleys, the hanger pin may need to be offset so it will not come into contact with the hand wheel. This can be accomplished by placing the required amount of washers to the hanger pin on both sides of the side plates.

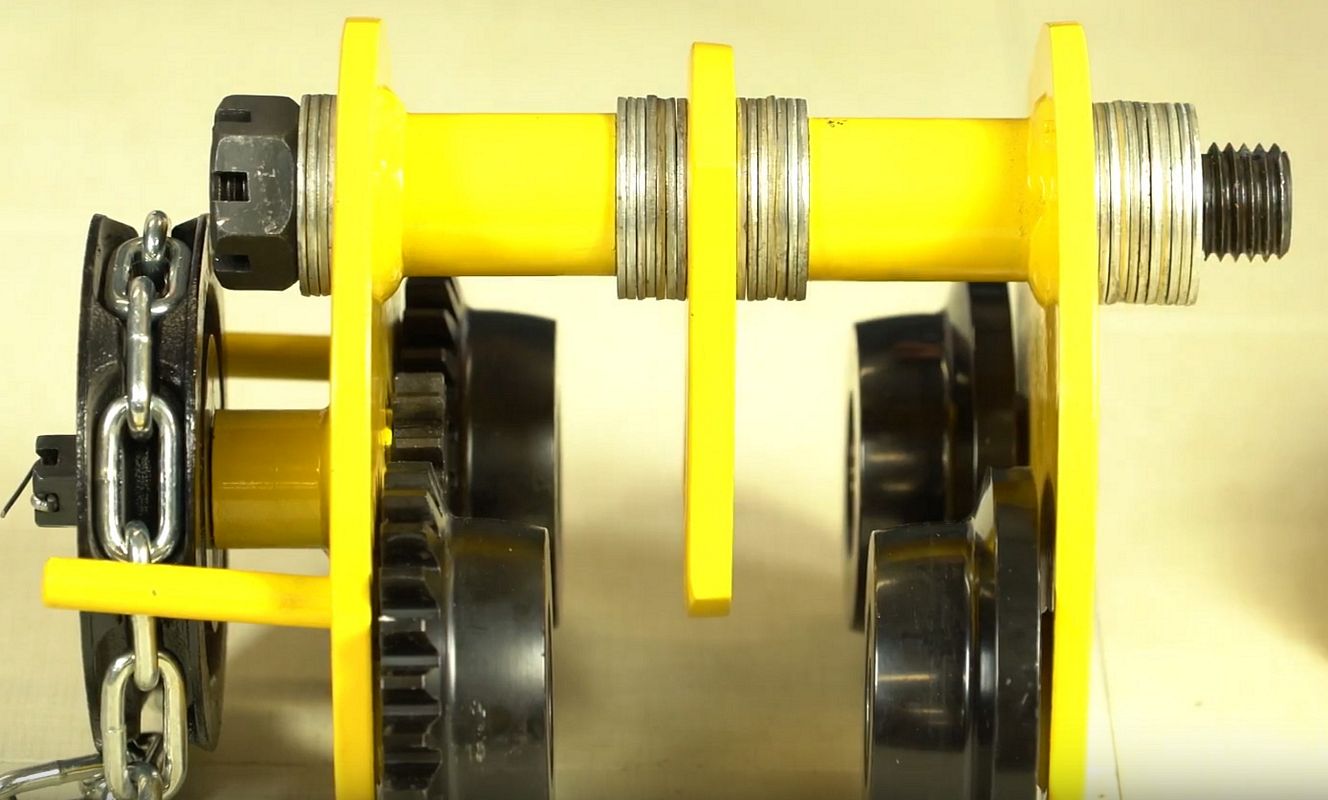

With the trolley loosely assembled, spread the side plates allowing the trolley wheels to be placed over the beam flange, so that the trolley will properly sit on the beam.

Tighten the nuts against the washers.

Insert the safety pins that are provided.

General Safety Information

Be sure to check the width of the beam before making your beam clamp or beam trolley selection.

Always take into consideration the load capacity of the beam and any other lifting devices used in your application.

Never attach a beam clamp or trolley to a beam that is fixed at an angle.

We hope this information has cleared up any questions or concerns you might have about the selection and installation of beam clamps and trolleys for your application. If you have any further questions, please Contact Us.

Back to Top