Galvanized and stainless steel aircraft cable and wire rope with quality, prices, and inventory levels unmatched in our industry. We carry Type 316, and Type 304 stainless steel, drawn galvanized, and PVC vinyl coasted cable in lengths up to 5000 ft. that are perfect for your industrial, commercial, or residential projects.

Instructional Videos on Steel Cable & Wire Rope

Explore our inventory of stainless-steel cable. We carry reels of stainless cable at types 316, 304, and Type 304 vinyl coated stainless steel cable up to 1000’ long. Watch our instructional videos on Stainless Cable and get tips on which cable to choose for different applications.

Watch our instructional videos on Cable and Wire Rope to get tips on which cable to choose for different applications. See our extensive guides below for more information to help make your decision before purchasing Cable and Wire Rope from E-Rigging.com. If you have any questions, contact our sales team, and we will be glad to assist you.

Wire Rope and Cable Knowledge Base

- Cable Strength Comparison

- Steel Cable Material Type Guide

- Cable Construction Guide

- Steel Cable Construction Explained

- Make it Safe: Wire Rope & Cable Warnings & Instructions

- E-Rigging Cable Feature Comparison Chart

- Stainless Steel vs. Galvanized Cable | Which Cable is Best for Your Project?

- Stainless Steel vs. Aircraft Cable Vs Steel Cable Explained

Table of Contents

Cable Strength Comparison

Cable Working Load limit / Rated Capacity Chart

This chart lists cable strengths by working load limit / rated capacity with a 5:1 design factor. Use the rated capacity when determining the strength requirements for your application. Be sure to understand termination efficiency ratings when terminating the cable. See our General Warning and Instructions document for more information on Rated Capacities , Design Factors , Termination Efficiencies , and Breaking Loads .

Cable Breaking Strength Chart

This chart lists cable strengths by breaking load. See our General Warning and Instructions document for more information on Rated Capacities , Design Factors , Termination Efficiencies , and Breaking Loads .

Never use Breaking Load ratings as your operational load. Use the Working Load Limits to determine the strength requirements for your application.

Steel Cable Material Type Guide

Drawn Galvanized Steel Cable

Galvanized (Zinc Coated) cable is the most popular type of steel cable. Our cable is coated using the drawn galvanizing process by individually drawing each wire of the cable through a molten zinc bath to completely coat the wires. This method is superior to other methods for corrosion resistance and finish quality. Galvanized cable has moderate corrosion resistance compared to stainless steel but is more ductile and resists bending fatigue more than stainless steel. Ductility and bending fatigue resistance is especially important when running over sheaves. Galvanized steel cable is stronger than stainless steel cable of the same diameter.

Type 304 Stainless Steel

Type 304 Stainless Steel cable is desirable choice when you need a balance of strength, ductility, and corrosion resistance between 316 stainless steel and galvanized steel cable. Also known as 18-8 Stainless steel, 304 Stainless Steel cable is stronger than 316 Stainless steel cable, but weaker than galvanized cable. It also has more corrosion resistance than galvanized steel but isn’t as resistant to corrosion as 316 stainless steel cable.

Shop our Type 304 Stainless Steel Cable

Learn all about Stainless Steel with our Stainless Steel Knowledge Base

Type 316 Stainless Steel Cable

Type 316 Stainless Steel cable is the most corrosion resistant cable of the common types available and is ideal for saltwater and chorine environments. It also has lower strength, and bending fatigue resistance than type 304 and galvanized cable. When using type 316 stainless steel cable with sheaves and blocks, be sure to select the largest diameter sheave suitable for the application to prevent splintering due to bending fatigue.

Shop our Type 316 Stainless Steel Cable

Learn all about Stainless Steel with our Stainless Steel Knowledge Base

Vinyl Coated Steel Cable

Our vinyl coated offerings are available in type 304 stainless steel and drawn galvanized. The base cable retains the same properties, and the vinyl coating enhances the cable. The coating is a clear PVC vinyl coating that is applied over the base cable to provide additional corrosion and abrasion resistance and give the cable a smooth finish that isn’t as rough if it comes into contact objects, animals, or people.

Cable Construction Guide

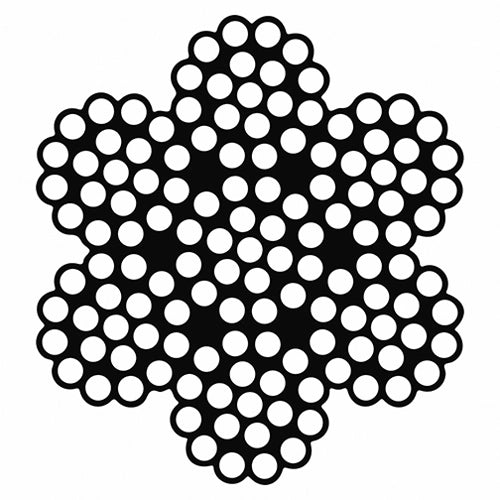

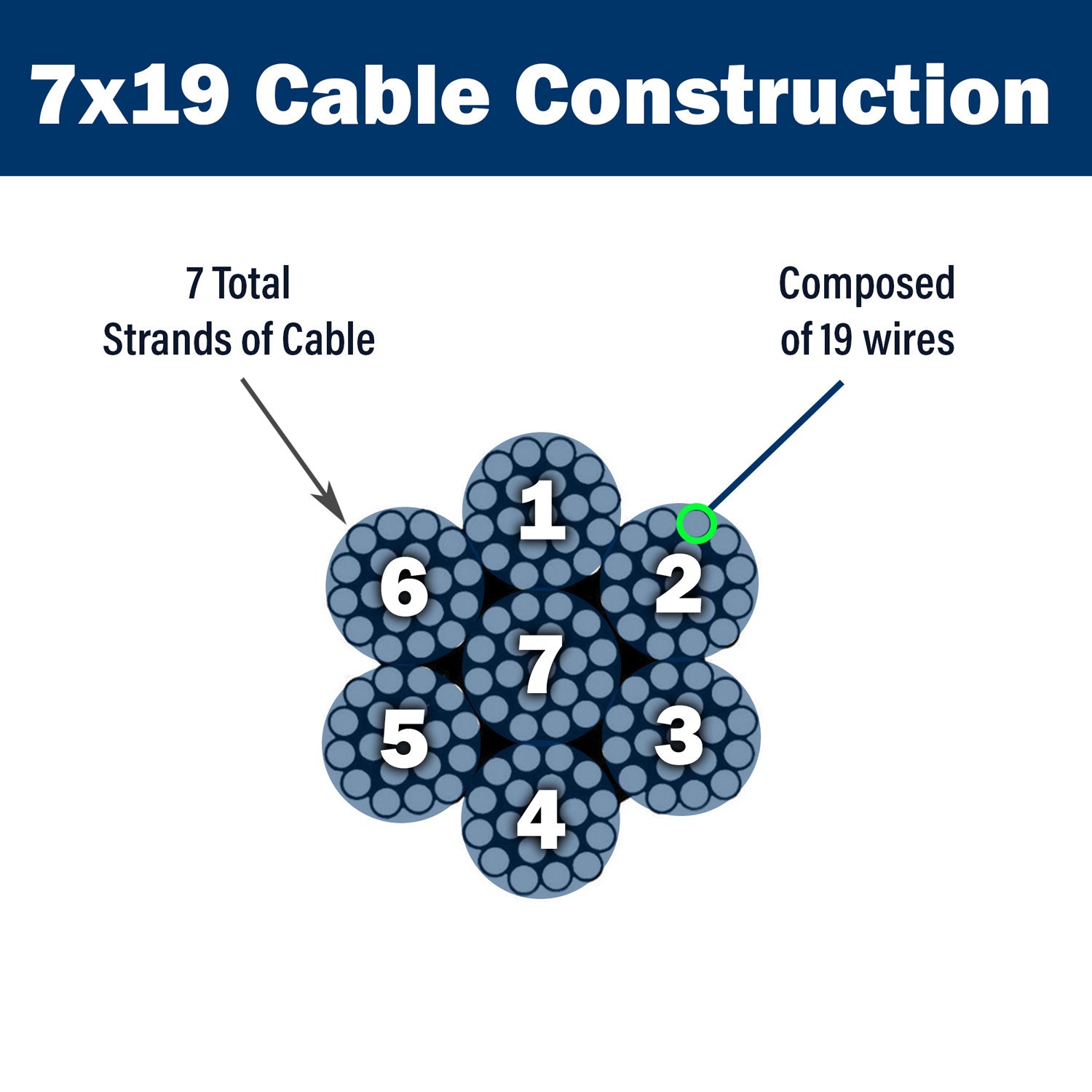

7 x 19 Construction

- Very Flexible

- Excellent Strength

- Fatigue Resistant

- Resists Crushing

Commonly used on small diameter pulleys, running rigging on sailboats, exercise equipment, winches and control cables. 7x19 is the best all around cable for most applications.

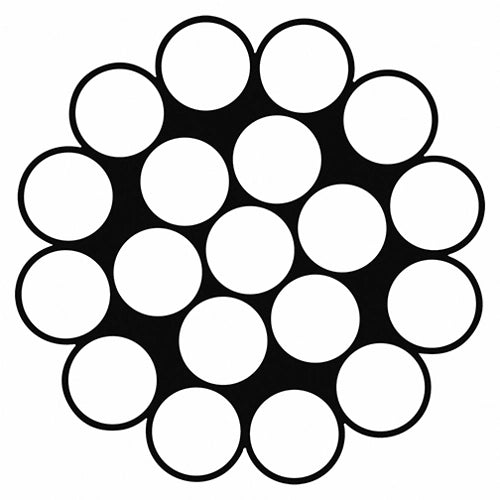

1 x 19 Construction

- Not Flexible

- Best for Cable Railing

- Stronger than 7 x 19 cable

- Good for Sailboat Rigging

- Suitable for guying applications

- Doesn't kink

Commonly used on cable railings, stationary rigging on sailboats, guy wires and push pull control cables. 1x19 is best suited for stationary applications.

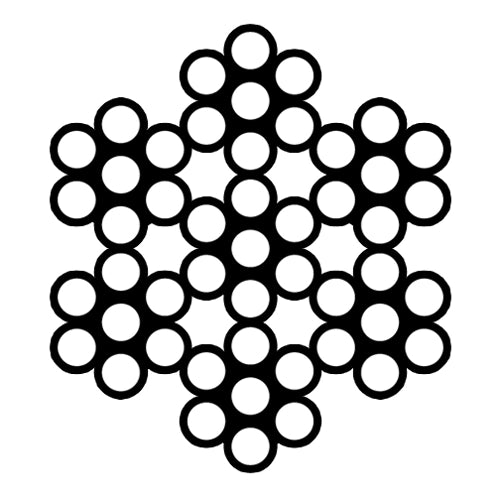

7 x 7 Construction

- Stiffer than 7x19, more flexible than 1x19

- Stainless 7x7 commonly used for cable railings, and marine applications

- Diameters less than 1/8" exhibit great balance of flexibility and strength

Small diameter 7x7 cable is great for use on pulleys and general use when diameters are needed smaller than available in 7x19 construction. Coated Stainless 7x7 cable is commonly used in marine applications or cable railings, while the galvanized offerings are used in general industry and agriculture.

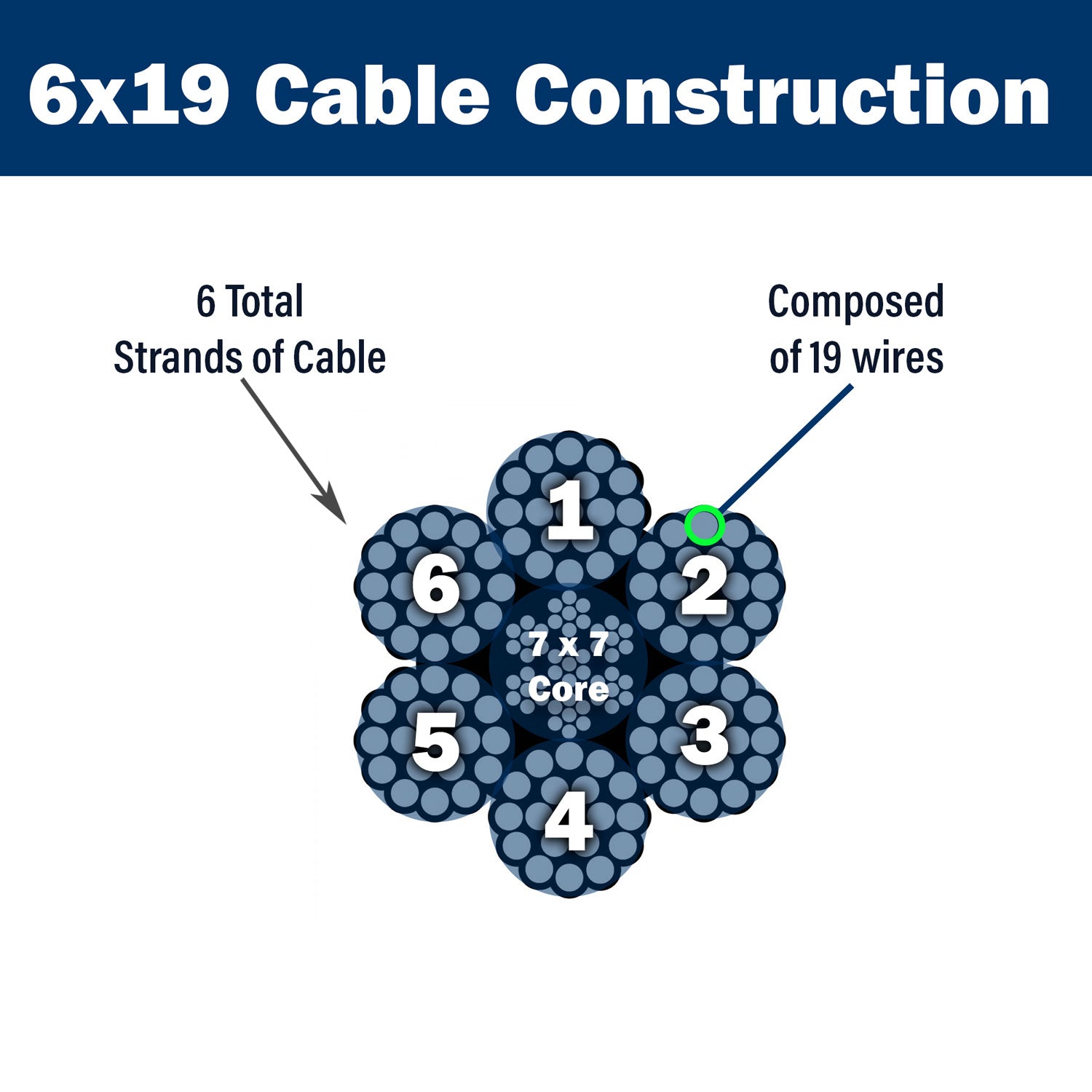

6 x 19 Construction

- Flexible in relation to diameter

- Excellent Strength

- Excellent Abrasion Resistance

- Resists Crushing

Each 6x19 wire rope strand begins with one large center wire that is covered by a layer of nine smaller wires and then an outside layer of nine larger wires. The 6x19 wire rope has larger outer wires than 7x19 which adds to an increased abrasion resistance but also decreases its fatigue resistance. This rope can stand up against abrasion or crushing on the drum.

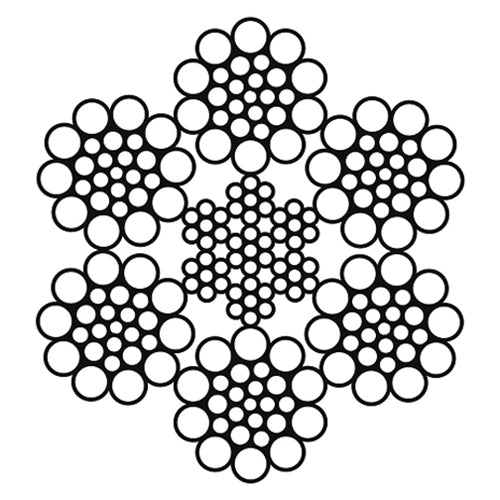

Steel Cable Construction Explained

When a project calls for lifting or suspending a load, cable and wire rope is often the first choice because of its cost, strength, flexibility, and versatility. Compared to a solid steel rod, steel cable is nearly as strong and has the capability to bend due to its construction of many small wires.

Different constructions yield different properties of the cable. For example, aircraft cables and wire ropes made with many small wires are more flexible, but the small wires are more fragile and susceptible to breaking. Steel cables with larger wires are more abrasion resistant but are much stiffer. The wires are twisted into strands, and the strands are twisted to form the cable. Using this method of twisting the wires and strands increases the strength, and reliability of the cable by balancing the load on all the wires. The wear resistance is also increased because the outer wires of the strands are equally exposed to wear and will wear more evenly.

What does 7x19 mean?

Aircraft cable is made from 7 strands of 19 wires each. There are 6 outer strands that are preformed (bent into a helix) and one center twisted strand. The construction of the center strand is similar to the outer strands, so it is included in the strand count. 7x19 and 7x7 cable is common for diameters 3/8” and smaller because of the simplicity of construction. Larger diameters typically use wire rope construction methods that allow much more versatility of features to match the intended application.

What is 6x19 IWRC?

6x19 wire rope may appear to have 7 strands total, but the center strand is actually a smaller diameter wire rope. IWRC stands for “Independent Wire Rope Core”, and allows for increased flexibility, bending fatigue life, and crush resistance. ½” diameters and above typically use wire rope construction methods.

Make it Safe: Wire Rope & Cable Warnings & Instructions

Wire rope is a machine, like any machine, it needs proper care and maintenance for optimal safety and long service life. Please read our Wire Rope & Cable Warnings and Instructions for more specific and detailed information.

E-Rigging Cable Feature Comparison Chart

| Cable Type | Corrosion Resistance | Flexibility | Strength | Ductility & Fatigue Resistance |

|---|---|---|---|---|

| 7 x 19 Galvanized Cable | 2/5 Stars | 5/5 Stars | 5/5 Stars | 5/5 Stars |

| 7 x 19 Vinyl Coated Galvanized Cable | 3/5 Stars | 4/5 Stars | 5/5 Stars | 5/5 Stars |

| 7 x 19 Type 304 Stainless Steel Cable | 4/5 Stars | 4/5 Stars | 4/5 Stars | 4/5 Stars |

| 7 x 19 Type 304 Vinyl Coated Stainless Steel Cable | 4/5 Stars | 3/5 Stars | 4/5 Stars | 4/5 Stars |

| 7 x 19 Type 316 Stainless Steel Cable | 5/5 Stars | 3/5 Stars | 3/5 Stars | 3/5 Stars |

| 1 x 19 Type 316 Stainless Steel Cable | 5/5 Stars | 1/5 Stars | 4/5 Stars | 2/5 Stars |

| 7 x 7 Hot Dip Galvanized Cable | 2/5 Stars | 2/5 Stars | 5/5 Stars | 5/5 Stars |

| 6 x 19 IWRC Galvanized Wire Rope | 2/5 Stars | 3/5 Stars | 5/5 Stars | 5/5 Stars |

E-Rigging 5 Star Rating System Explained

You'll see E-Rigging's 5-Star rating system throughout our site. We rate the cable's properties in relation to each other.

Recently viewed

- Opens in a new window.