At E-Rigging, we offer a wide selection of wire rope clips, including options in galvanized, zinc-plated, and stainless steel finishes. Our wire rope clips are made to meet the demanding needs of construction, marine, and industrial projects. Available in sizes from 1/8" to 3/8", these clips ensure a firm and dependable connection for your wire rope or cable assemblies. Constructed from materials that resist corrosion and provide strength, our clips are ideal for heavy-duty use. Suitable for harsh environments, including marine settings, these clips are straightforward to install, providing a firm grip on your riggign assemblies. Perfect for construction projects, marine applications, and industrial use, professionals choose our wire rope clips for their trusted performance in critical applications. Explore our detailed specifications to find the right wire rope clip for your needs, ensuring the best performance and safety in your operations.

Featured Project Blogs

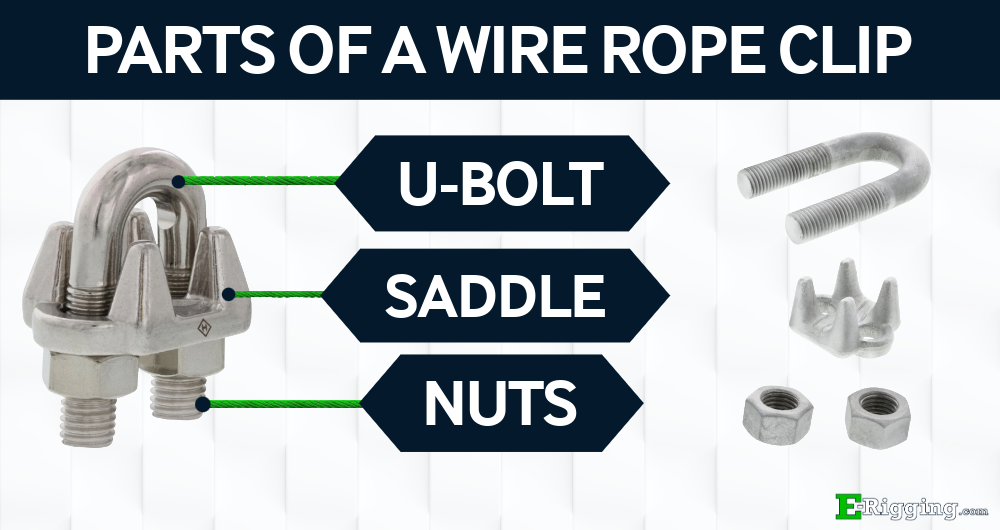

E-Rigging.com has a full line of wire rope clips in galvanized, zinc plated, and stainless steel finishes to best suit your job’s requirements. A wire rope clip, also called a clamp, cable clamp, wire rope clamp, U-Clip, U-Clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-shaped bolt, a forged or cast saddle and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is then fitted over the ropes on to the bolt (the saddle includes two holes to fit to the U-bolt). The nuts secure the arrangement in place.

In order to achieve maximum strength on vinyl coated cable, please remove the vinyl coating from the cable in the area where the wire rope clip, sleeve, or button will be affixed. When selecting termination fittings for vinyl coated cable, select the fitting that is sized to the diameter of the cable, not the diameter of the coating. If you affix the termination fitting over the vinyl coating, the strength of the assembly will be greatly reduced.

Count on E-Rigging for quality, sturdy stainless steel wire rope clips to help secure loose ends. As knowledgeable experts in the rigging industry, we work hard to provide you with reliable products that will last you for many years to come. For more information on our wire rope clips, browse our online catalog! For questions or inquiries on our stainless steel wire rope clips, contact us!

- For more information, Read the Blog on Installing Wire Rope Clips

- For more information, Read the Blog on Selecting Wire Rope Clips

Wire rope clips are fittings used to make an eye or join two cable or wire rope ends together. They are a simple fitting that can be installed in the shop or in the field. There are three basic types of steel wire rope clips – Drop forged, malleable iron and fist grip types. The intended application for the wire rope or cable should determine which type to use.

For important or critical applications and if to be used in overhead lifting or suspending, always use standard drop forged type and drop forged fist grip type clips. Never use a malleable iron type clip for these applications.

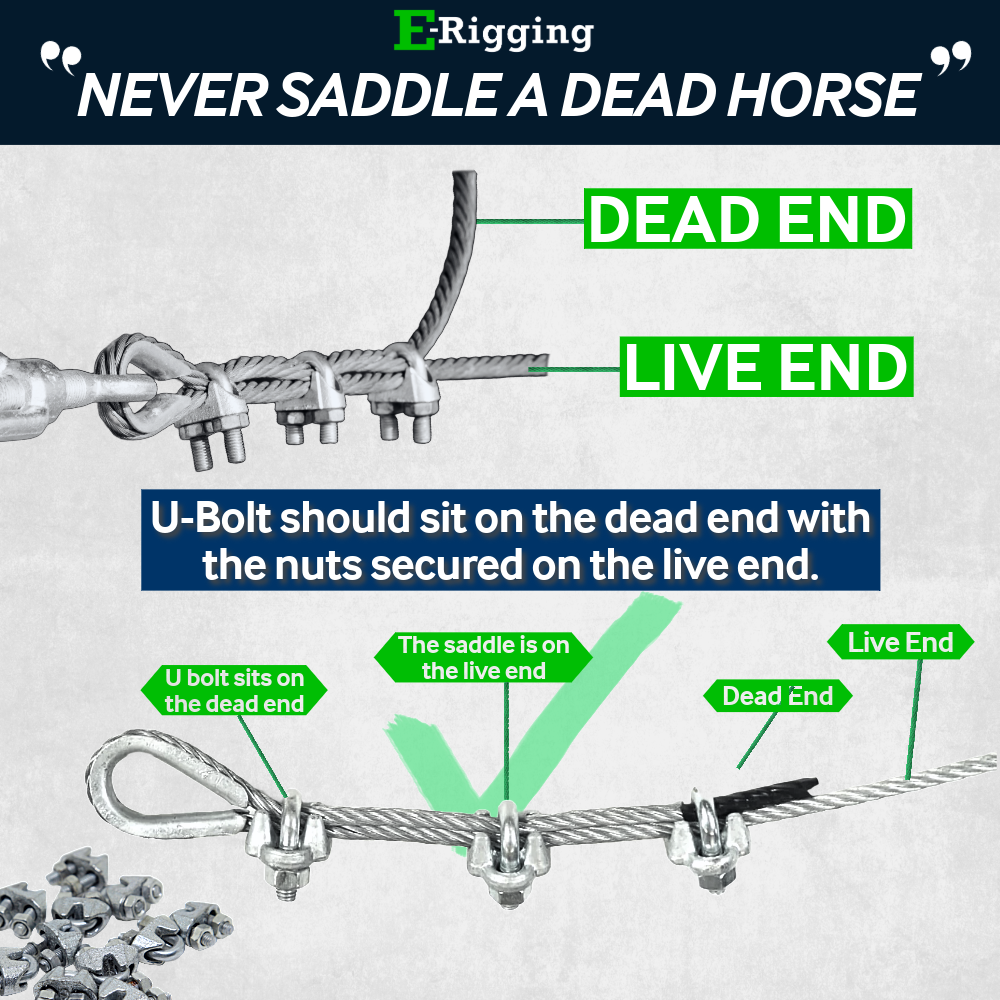

The components of wire rope clips are the saddle, the bolt(s) and the nuts.

Forging is the practice of heating a piece of steel and hammering it to shape. Doing this gives the steel linear grain structure and greater strength. In the drop forged clips, the saddles are the parts that are drop forged. The saddles of malleable iron clips are made from a type of steel with poorer strength qualities and is cast into shape and therefore, has a granular microstructure and not linear. This means the cast malleable saddle can yield under greater loads and cause the wire rope or cable to slip through and potentially fail. In general, forging is stronger than a casting.

For clips to work properly and gain their design efficiency (see charts), both the minimum number of clips required and the nuts must be torqued to the prescribed foot/pound rating.

In drop forged and fist grip type clips, the saddle pieces are hot dip galvanized and the bolts and nuts are electro-galvanized (zinc plated). With malleable clips, the saddles, u-bolts and nuts are electro-galvanized.

All three types of clips that E-Rigging sells conform to U.S. Federal Specification FF-C-450. It should be noted that stainless steel wire rope clips do not conform to this federal specification.

Wire Rope Clips FAQs

A wire rope clip consists of three main parts: the U-bolt, the saddle, and the nuts. The U-bolt is a U-shaped bolt that fits around the wire rope, the saddle is a plate that sits on top to distribute the clamping force, and the nuts secure the assembly by tightening onto the U-bolt ends.

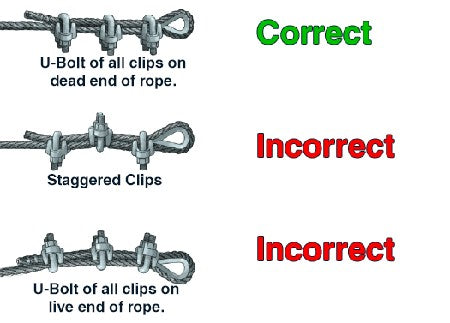

It is important to ensure wire rope clips are installed properly. Incorrect installation can reduce the working load limit by 40%. Below are general guidelines for installing wire rope clips. After proper assembly, a wire rope clip termination can be expected to hold 80% of the breaking strength of the wire rope for cable diameters 1/8” through 7/8”.

This number is typically referred to as termination efficiency.

Sizes 1” through 3 ½” has a termination efficiency of 90%.

- Ensure the saddle is on the live end of the wire rope.

- Torque the nuts to the specified foot-pound rating.

- For optimal performance, use the correct number of clips as per guidelines.

Clip Installation Diagram

Wire rope clips are fittings used to create an eye or join two wire rope ends together. There are three main types: drop forged, malleable iron, and fist grip. Drop forged clips are the strongest, as their saddles are shaped by heating and hammering steel, providing a linear grain structure. Malleable iron clips, cast into shape, have a granular microstructure and lower strength, making them less reliable under heavy loads. Fist grip clips also feature strong, hot-dip galvanized saddles. The choice of clip depends on the wire rope’s intended application. All E-Rigging clips meet U.S. Federal Specification FF-C-450, except for stainless steel clips.

To calculate the termination efficiency of wire rope clips, follow these steps:

- Determine the Cable Breaking Load: Identify the maximum load the cable can handle before breaking. For example, if the cable breaking load is 2000 lbs.

- Determine Cable Efficiency: Check the efficiency percentage for the specific cable size. For a 1/8” cable, the efficiency is typically 80%.

- Calculate Termination Breaking Load: Multiply the cable breaking load by the efficiency percentage. For example, 2000 lbs x 0.80 = 1600 lbs.

- Divide by the Design Factor: Divide the termination breaking load by the design factor (usually 5:1 for safety). For example, 1600 lbs ÷ 5 = 320 lbs.

- Ensure you use the minimum number of clips and torque the nuts to the specified foot/pound rating for proper functioning and efficiency. For critical applications and overhead lifting, use standard drop forged or drop forged fist grip clips. Avoid using malleable iron clips for these applications. When using vinyl-coated cables, remove the coating where the clip will be affixed and choose fittings sized to the cable diameter, not the coating diameter.

The number of wire rope clips needed for a secure connection depends on the diameter of the wire rope. Generally, for ropes up to 1/2" in diameter, at least three clips are required. For ropes 5/8" to 7/8", four clips are recommended, and for ropes 1" to 1-1/4", five clips are necessary. E-Rigging provides the number of required rope clips for a secure connection at the bottom of every product page for your reference.

Wire rope clips can be reused if they are in good condition without any signs of wear, deformation, or corrosion. However, for critical applications, especially those involving safety, it is recommended to use new clips to ensure maximum reliability and performance.

Yes, special considerations are needed for wire rope clips used with coated cables. It is recommended to remove the coating in the area where the clip will be affixed to ensure a secure grip. Additionally, select a clip that is sized for the cable diameter, not the diameter of the coating.

Wire rope clips should be checked and retightened regularly, especially after the initial installation. It's recommended to inspect them after the first load application and periodically thereafter, depending on the frequency of use and load conditions. Regular maintenance ensures the clips remain secure and safe.

Fist grip wire rope clips, also known as double saddle or double grip clips, have a saddle on both sides of the U-bolt, providing a more secure grip on the wire rope. Unlike standard U-bolt clips with a single saddle, fist grip clips distribute the clamping force more evenly, reducing the risk of rope deformation and slippage.

E-Rigging stands out due to our commitment to providing high-quality rigging products at competitive prices. With a wide range of products, knowledgeable staff, and a user-friendly shopping experience, we aim to be your go-to source for all rigging and cable needs. Whether you are a professional rigger or a DIY enthusiast, E-Rigging is equipped to supply everything you need for your lifting, securing, and rigging applications.