Below is our video explaining different wire rope clips and the different environments in which each wire rope clip is best suited.

If you would prefer a text and picture explanation of the video, keep scrolling.

If you are seeking information on the proper installation of wire rope clips, please look to our Wire Rope Clip page, our YouTube Channel, or the direct link to the video at the end of this article.

Wire Rope Clips are used to form a load bearing eye at the end of a wire rope/cable and to connect two cables together using a lap splice.

E-Rigging carries a variety of wire rope clips in different materials, styles, and coating types. These wire rope clips are suited for less than permanent applications. They can be secured with common hand tools and are a cost-effective alternative to swaged sleeves, if you only have to make a few assemblies.

- Most Corrosion Resistant

- Best for outdoor applications as they are highly resistant to corrosion, especially in or near saltwater environments.

- Lower cost than stainless steel

- Suited for outdoor environments.

- Not as corrosion resistant as stainless steel wire rope clips.

- May be used outdoors but may exhibit signs of surface rust quicker than Hot Dipped Galvanized wire rope clips; especially if used in rain, snow, salt air, or saltwater environments.

- Best used in applications that do not involve overhead suspending and are non critical.

- Cost effective alternative to drop forged wire rope clips.

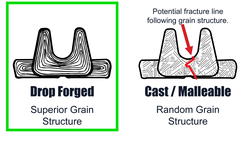

- Slightly less reliability than drop forged wire rope clips due to the difference in manufacturing processes.

- They can be used as an alternative to wire rope clips in some applications.

- Most cost-effective stainless-steel option.

- Suitable for light duty applications.

- Double clamps can hold a little more load than the single clamp.

- Feature an aesthetic design that some customers use as the deciding factor when given the choice between using a wire rope clip or cable clamp.

IMPORTANT: The working load limit of the cable assembly will decrease if the vinyl coating is not stripped from the cable. This occurs because the saddle and u-bolt are making contact with the soft and pliable vinyl coating and not the wire rope, which may cause slippage in the assembly and can lead to failure. It is also important to note that different companies size vinyl coated cable differently. E-Rigging lists vinyl coated cable by the cable diameter without the coating. The vinyl coating adds a little thickness to the cable. We have the finished/ final diameter of the cable with the coating listed on our website.