Discover a comprehensive inventory of hoist rings featuring our top-notch brands, LFT and ADB. Whether you need standard or metric sizes, our hoist rings are engineered to meet your lifting demands. With precision-crafted designs and unmatched quality, we offer a range of options to meet your lifting operations.

LFT Swivel Hoist Ring Features

- Features a large attachment point for greater connection versatility.

- 5:1 Design Factor and 100% load rated throughout 360° swivel and 180° pivot.

- Alloy steel forged bails 200% load tested and Non-Destructive tested via the Resonant Acoustic Method per ASTM E2001.

- Alloy Steel and Stainless-Steel machined components are Non-Destructive tested via the Resonant Acoustic Method per ASTM E2001.

- Raised lettering on forged bail showing heat code and Manufacturer for traceability.

- Meets ANSI/ASME B30.26.

- Permanently marked with an individualized serial number, load rating, torque specification, and part number.

- Geomet coated for superior corrosion resistance and powder coated for a high-visibility durable finish.

FAQs - Swivel Hoist Rings

- Heavy machinery needs to be repositioned: Swivel hoist rings facilitate the safe lifting and turning of large machines, reducing the risk of damage and improving workflow efficiency.

- Complex load movements are required: In industrial settings, such as automotive manufacturing or aerospace assembly, swivel hoist rings allow for the precise movement of components during assembly processes.

- Multi-directional lifting is necessary: For projects involving the installation of structural steel or large piping systems, swivel hoist rings provide the flexibility to lift and align components accurately, even at challenging angles.

- Safe lifting of irregularly shaped objects: Swivel hoist rings are ideal for handling objects with non-standard shapes or weights, ensuring balanced lifting and reducing the risk of tipping or slipping.

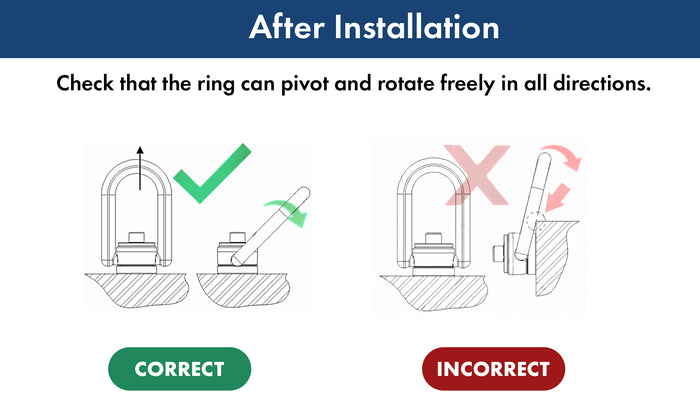

After installation, always check that the ring can pivot and rotate freely in all directions, as illustrated in the graphic. Ensuring free movement prevents binding and uneven stress distribution during angular lifts. The correct setup allows the swivel hoist ring to operate effectively and safely, while an incorrect setup can lead to restricted movement and potential failure during lifting operations. Regular inspections and proper installation are key to maintaining the safety and functionality of swivel hoist rings.

- Do Not Exceed Load Capacity: Always adhere to the rated load capacity.

- Avoid Shock Loading: Lift gradually to prevent sudden forces that can damage the hoist ring.

- Check Torque Regularly: Ensure mounting screws are tightened to the recommended torque.

- Inspect Regularly: Perform regular inspections for wear and damage.

- Use Proper Materials: Ensure the tensile strength of the parent material is at least 80,000 PSI.

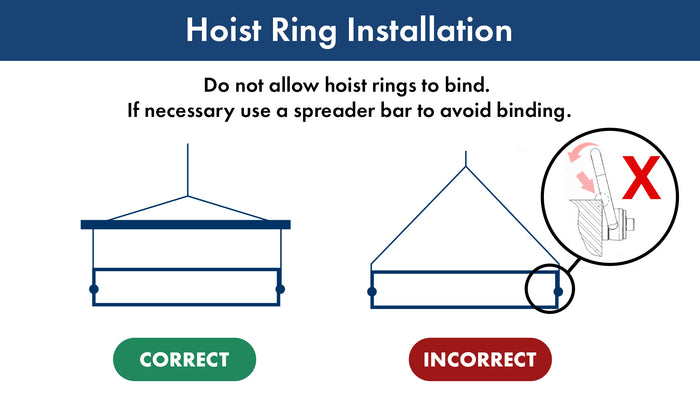

- Avoid Binding: Use a spreader bar if necessary to prevent binding.

- Proper Mounting: Ensure the mounting surface is flat and smooth, and avoid using spacers.

- Bail (or Ring): The part that the lifting hook or shackle attaches to, typically made from high-strength steel.

- Base or Mounting Plate: The part that attaches to the load, designed to be bolted or screwed securely.

- Swivel Mechanism: Allows the ring to rotate 360 degrees, providing flexibility and preventing the load from twisting.

- Pivot Mechanism: Enables the hoist ring to pivot in various directions, accommodating angular lifts.

- Mounting Screws/Bolts: Used to secure the hoist ring to the load, must be tightened to the specified torque for safety.

- Grease Fittings (if applicable): Some hoist rings include grease fittings to ensure smooth operation and reduce wear.

- Select the Right Hoist Ring: Match the load capacity requirements.

- Prepare the Mounting Surface: Ensure it’s flat, smooth, and perpendicular.

- Drill and Tap Holes: Follow manufacturer specifications.

- Tighten Screws/Bolts: Use a calibrated torque wrench.

- Check Movement: Ensure the ring pivots and rotates freely.

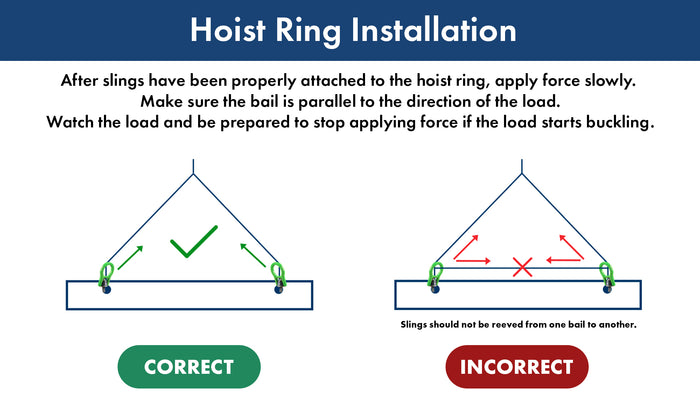

- Attach Slings Correctly: Align with the load direction; avoid crossing.

- Prevent Binding: Use a spreader bar if necessary.

- Regular Inspections: Check for wear and maintain torque.

By adhering to these steps, you guarantee safe and effective use of your LFT swivel hoist rings. For detailed instructions and more rigging tips, visit E-Rigging.com.

LFT hoist rings offer several practical advantages:

- Versatile Attachment: The large attachment point allows for greater connection flexibility.

- Safety Factor: Designed with a 5:1 safety factor, they are load-rated for 360° swivel and 180° pivot.

- Thorough Testing: Both alloy steel and stainless steel components are tested using the Resonant Acoustic Method per ASTM E2001.

- Traceability: Forged bails include raised lettering with heat code and manufacturer details.

- Standards Compliance: They meet ANSI/ASME B30.26 standards and are marked with serial numbers, load ratings, torque specifications, and part numbers.

- Corrosion Resistance: Geomet coating and powder coating enhance corrosion resistance and provide a durable finish.

Designed and made in the USA, LFT is a dependable brand for load fastening technology.