Bundle and Save 10% with E-Rigging’s Exclusive Trucker Bundles!

3 Sizes fit chain from 5/16” -5/8”

Get Your Binders Quick: In-Stock Items Ship Immediately, Orders over $299 ship free!

Why use Speedbinders? Safe, Efficient, and Tough Features

ENHANCED SAFETY FEATURES

Reduced risk injury with no pinch points from operating lever.

HIGHEST TENSION

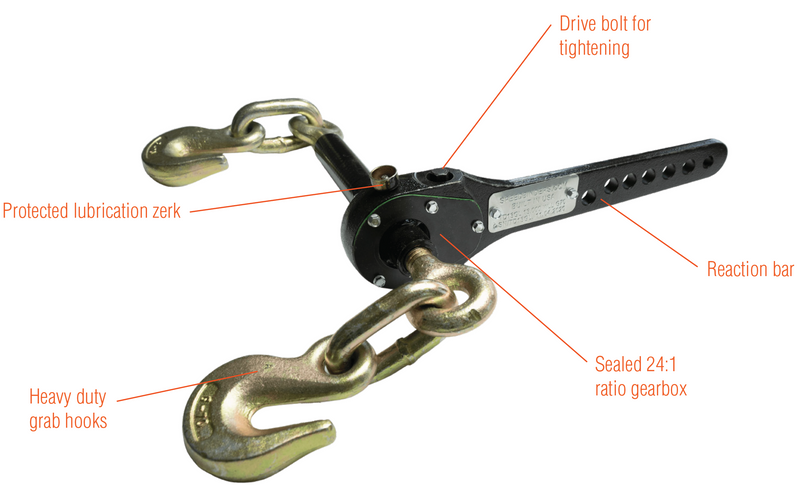

24:1 gear ratio generates higher tension than conventional binders

MORE ERGONOMIC

Dramatically lowers strain-related injuries and claims by eliminating repetitive motions.

EASY TO OPERATE IN TIGHT SPOTS

Eliminates the need for ratcheting or levers, making it much easier to operate in tight spaces like inside steel coils.

QUICKER

Tie-down and release times are up to 3x faster*, leading to significant time and cost savings.

UNMATCHED TENSION RETENTION

Maintains tension throughout the journey with the handle functioning as a reaction bar.

LONGER LASTING

The sealed gearbox, zinc plated hooks, links, and threaded rods provide protection. The ability to quickly run threads inside the barrel keeps them clean and lubricated, extending the binder's lifespan by up to 4x*.

TAMPER-RESISTANT

Reduced risk of stolen tools or cargo since a drill is required to loosen the binder. *Compared to traditional ratchet binders

Replacement Parts

Frequently Asked Questions about the Speed Binders

Drive Load binders are high-quality drill operated load binders that use a worm gearbox to tension binder chains tighter and faster than other binders on the market. The lever arm works as a reaction bar and braces against the trailer deck or other solid object with a light five-to-seven-pound force to prevent the binder from loosening. Speedbinders Torque Drive Load Binders allow drivers to experience less shoulder strain, easier operation, and faster tie down/release times while having high chain tension to virtually eliminate loosening from tire mash.

No, a 14mm socket powered by a cordless drill is the recommended method, but other tools can be used. A 14mm or 9/16” wrench or socket, an adjustable wrench, and/or pliers can be used to operate the torque drive load binder. While using a drill is the preferred method of operation to fully utilize the speed and ergonomics of the design, you won’t be stuck with an inoperative load binder if you don’t have a drill.

Torque Drive binders use a sealed gear box filled with grease and resistant to outside debris. Newly applied grease further pushes out any debris or grime trying to enter. Compared to a conventional ratchet binder, there is no flipping pawl assembly to freeze or bind. The drill-operated and 24:1 gear-reduced design powers through dirt, snow and ice on your threads rather easily.

The zinc plated end fittings and threads, and the durable painted body withstand corrosion exceptionally well compared to the competition, and the ease at which you can quickly fully retract the threads into the barrel encourage storage with the fewest critical parts exposed. These binders have been built and tested on over 20,000 trucks along the shores of Lake Erie, in the snow belt of the Great Lakes, and across the country for years satisfying over 20,000 trucks.

A NON-IMPACT drill with approximately 800 lb-in torque output will provide adequate tensioning of the load. Ideally a drill with multiple speed settings will allow you to rapidly adjust the binder in high speed, and tighten down the load in low speed. A drill with a torque limiting adjustment setting also helps to set chain tension to your liking. Consistent rotational torque applied to the hex head and worm gears will ensure long service life of the load binder.

Here is a list of drills from popular quality brands that are known to work well with Speedbinders Torque Drive binders:

| Make | Type | 2903-20 |

|---|---|---|

| Milwaukee | M18 Fuel ½” Drill/Drivers | 2903-20 |

| DeWalt | 20V Max XR ½” Drill/Drivers | DCD991P2 |

| Makita | 18V LXT Brushless ½” Drill/Drivers | XFD16Z |

| Makita | 40V XGT Brushless ½” Drill/Drivers | GFD01Z |

| Bosch | 18V Brushless ½” Drill/Drivers | GSR18V-975CN |

| metabo | 18V Brushless ½” Drill/Drivers | BS 18 LTX BL I |

If the drill battery goes dead, you can always use 14mm wrenches, sockets or pliers top operate the binder. A quality 18 or 20 volt drill typically lasts about 40 full cycles. Depending on the loading schedule, 40 cycles could last anywhere from two days to 2 months. Due to the ease and speed that the Torque Drive binders operate, users quickly treat their drill and battery as their best friend helping them get on the road quicker. The time and effort saved binding easily justifies a spare battery, charger and on-board inverter.

Impact drills/ drivers are not recommended for use as they reply on an impulsive hammer effect to generate torque. Shock loading the hex head of the drive bolt will reduce the service life by half. A quality NON-IMPACT drill/ driver is the recommended tool and can achieve 2000-3000 cycles of use from the drive bolt. Replacement drive bolts are considered wear items, are easily replaced, and available for purchase here: Speedbinders Replacement Drive Bolt

Use of a ½” impact wrench/drill/driver on the load binder immediately voids the warranty of the Torque Drive Binder.

The handle is designed to be a reaction bar which works best when it is positioned against the floor of the trailer or up against something. It won't rotate the barrel unless it is positioned for full 360-degree rotation. If you must operate the unit by hand, a 14mm or 9/16” wrench or socket, an adjustable wrench, and/or pliers is needed.

Companies have found that avoiding just one workman's compensation injury paid for all the binders 10 times over. If you are an owner/operator, how much money would you lose if you had to be down for two weeks due to a torn rotator cuff or tendinitis? The investment is not much more compared to a normal binder. Also, the binding time, DPF regen time, and fuel savings while binding add up to more than compensate for the initial cost of a set of Torque Drive Load binders.

Yes, you can. Any quality 18-volt or 20-volt drill will work. However, to get the maximum performance, speed and tightness from your Torque Drive binders, we recommend a drill from the list below. A typical economy drill doesn’t have the required torque while the drills listed below all have over the 800 lb-in torque recommendation. If you use binders daily, a quality high- torque drill will allow you to fully utilize the efficiency gains that Speedbinders Torque Drive Binders can provide. If you use the binders three or four times a month, your average drill may be the best choice for your scenario.

| Make | Type | 2903-20 |

|---|---|---|

| Milwaukee | M18 Fuel ½” Drill/Drivers | 2903-20 |

| DeWalt | 20V Max XR ½” Drill/Drivers | DCD991P2 |

| Makita | 18V LXT Brushless ½” Drill/Drivers | XFD16Z |

| Makita | 40V XGT Brushless ½” Drill/Drivers | GFD01Z |

| Bosch | 18V Brushless ½” Drill/Drivers | GSR18V-975CN |

| metabo | 18V Brushless ½” Drill/Drivers | BS 18 LTX BL I |