Stay safe this winter with our pewag tire chains for cars, trucks, SUVs, and commercial vehicles. Designed for easy installation and maximum traction on snow and ice, our durable chains fit all tire sizes and meet legal requirements. Shop now for heavy-duty snow chains, affordable tire chains, and accessories to keep you on the road, no matter the weather.

Step 1: Choose Your Application

Tire Chain Feature Information (Click Icons to Learn More)

Road Surface

Tension Method

Chain Pattern

Chain Link Profile

Tire Configuration

Other Features

Shop Tire Chains using Filters

E-Rigging is excited to offer the highest-quality tire chains from pewag.

At E-Rigging, we’re proud to bring you Pewag tire chains—trusted worldwide for over 500 years and made right here in the USA. These chains are built tough for winter’s worst, offering dependable traction for all types of vehicles, from SUVs and light trucks to semi trucks and heavy-duty off-road equipment.

Whether you’re outfitting your semi truck for icy highways, adding safety chains to a family SUV, or preparing a fleet for harsh winter conditions, we’ve got a chain that fits the job. Choose from Pewag’s starWave chains for extra grip, studded snow chains for icy roads, or double-spaced chains for maximum durability and stability.

Our selection is ready for quick, easy online ordering, and with E-Rigging’s tire chain calculator, finding the best Pewag tire chains for your vehicle is simple. Get ready to drive with confidence—our chains are ready to ship so you can stay safe and keep moving all winter long.

Tire Chain Reference Information

Snow / Traction Chain Frequently Asked Questions

Yes, some tire chains are rated for limited use on paved surfaces. pewag Tire Chains come in the following surface conduction ratings:

- Off Road Only

Chains designated “Off Road Only” should not be used on paved surfaces. These tire chains have chain profiles that are very aggressive to deliver maximum traction and will damage paved road surfaces and prematurely wear the tire chains. - Highway

Chains designated for highway use are designed to deliver additional traction and a long service life while not damaging snowy or icy paved surfaces. As with all tire chains, extended use on clear paved surfaces will cause excessive chain wear. - Highway & Off Road

Chains rated for paved road usage can also be used Off Road but will have less traction Off Road than Off Road dedicated chains.

- Cam Assisted

These traction chains are supplied with built-in Cam tensioners and a Cam tensioning tool for easy, quick, and secure tensioning of the tire chain to the tire. - Manual without Cams

These traction chains are supplied with a manual lever tensioner to provide adequate tension when installed properly.

- Ladder Style

Ladder Pros:- Effective in Deep Snow and Mud: Ladder chains excel in deep snow by providing good grip as they dig into the surface like a paddle tire.

- Easier Installation: Their straightforward design makes them easier and quicker to install, which is helpful in challenging conditions.

- Cost-Effective: Generally, ladder chains are less expensive than zig-zag chains.

- Bumpier Ride: The design can cause a bumpier ride due to the gaps between the cross chains, leading to a less smooth driving experience.

- Less Continuous Traction: The gaps between cross chains can result in less consistent traction, particularly on ice and packed snow.

- Limited Lateral Stability: Ladder chains offer less side-to-side stability, which can increase the risk of sliding sideways on slick surfaces.

- Zig Zag

Zig Zag Pros:- Continuous Traction: The zig-zag pattern offers more consistent contact with the road, providing excellent traction, especially on ice and packed snow.

- Smoother Ride: The evenly distributed chain pattern generally results in a smoother ride with less bumpiness compared to ladder chains.

- Good Lateral Stability: The pattern helps with side-to-side stability, reducing the risk of sliding on slick surfaces.

- Higher Cost: Zig-zag chains are often more expensive due to their complex design.

- Less Effective in Deep Snow: They may not dig into deep, loose snow as effectively as ladder or H-pattern chains.

- H-Pattern

H-Pattern chain is often used in tire applications with deep treads and is designed to keep the cross-chain riding above the treads rather than falling into the valleys of the tire tread. Due to the longitudinal and latitudinal pattern of the cross chains, this chain is extremely effective on rough and uneven terrain.

- Starwave Square Link

Starwave Chain features a unique wave-shaped link pattern which increases the surface area in contact with the ground enhancing grip. Made from nickel manganese alloy steel, which is heat-treated for increased hardness and durability. The square-shaped links, provide more surface area for better traction compared to traditional round links. Square links also tend to wear more evenly, are self-cleaning, and reversible, extending the life of the chain. - Star Stud

pewag’s Star Stud revolutionary 8-sided design is proven to outlast and outperform the competition. Breaking the mold of conventional round studs; pewag’s 8-sided stud allows for a deeper hardening on each individual piece for longer service life. This chain is engineered for the most aggressive off-road applications. Built to last and Made in USA! - Square Link

The chains are made with nickel manganese alloy square link wear up to 8 times longer than conventional twist link tire chains while giving you up to 32% more traction. These chains are also reversible to extend the service life of the tire chain

- Dual Triples

Dual Triple refers to a specific configuration of tire chains that are designed to cover a set of dual tires (two tires mounted side by side on the same axle). In a "dual triple" configuration, there are three sets of cross-chains that run across each tire in the dual set, which helps to ensure a more even distribution of traction and better grip. This configuration is particularly useful in severe conditions where maximum traction is needed. - Single

Tire chain designed to cover a single tire.

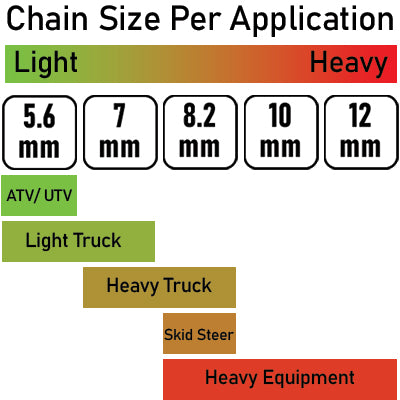

pewag tire chains come in a variety of diameter sizes that are aimed to provide the best mix of durability, traction, and ride comfort for your application. Typically, larger chains are suited for heavier more abusive equipment and environments, and smaller chains are suited for lighter equipment and better ride comfort. The recommended sizes are designed to prove adequate traction and durability for your vehicle size.

- Larger Chains:

- Suited for heavier equipment

- Handles rougher environments and forces exerted on the chains

- Rougher ride

- More costly

- Smaller Chains:

- Suited for lighter equipment

- Better ride comfort

- Adequate durability and traction for properly sized equipment

- Less costly

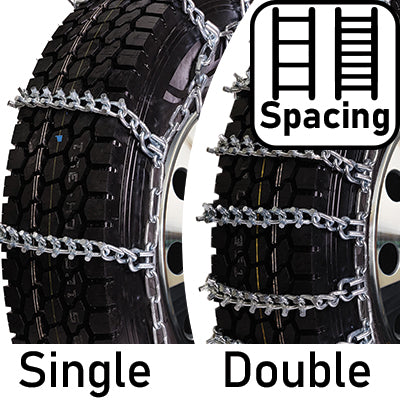

Cross chain spacing is an import consideration for your application, and there are a few terms that can describe the spacing configuration:

- Single Spacing / 4-Link Spacing

- Fewer cross chains per tire

- Typically spaced every 4 side chain links apart

- Moderate traction in light to medium snow & ice conditions

- Easier to install

- Less costly

- Double Spacing / 2-Link Spacing

- More cross chains per tire

- Typically spaced every 2 side chain links apart

- Superior traction in deeper snow & ice conditions

- More difficult to install

- More costly

Pre-cut replacement cross chains are set to a certain number of links and come equipped with end hooks to replace OEM cross chains that have become damaged or excessively worn.

Bulk cross chain comes in 50 and 100 ft lengths and are especially cost effective for fleets or other situations where a user replaces lots of cross chain due to heavy usage. Side Chain hooks must be purchased separately.

pewag rubber Glacier tensioners are designed to reduce noise and vibration and provide a tighter fit for any tire chain.

For semi trucks, the number of snow chains required can depend on local laws, road conditions, and the specific type of semi-truck. Generally:

- Standard Drive Axle Requirements: Most regulations require at least four chains on the drive axles—two chains per side on each of the two drive wheels. A Dual Triple tire chain can cover a set of duals with one chain.

- Additional Chains for Severe Conditions: In very icy or mountainous areas, you may need six chains (four on the drive wheels and two on trailer tires or additional axles) for added stability and traction. A Dual Triple tire chain can cover a set of duals with one chain.

- Compliance with Chain Laws: States like Colorado, California, and Washington have specific chain laws for trucks during snow season. For example, Colorado’s chain law often requires six chains for full compliance on mountain passes. A Dual Triple tire chain can cover a set of duals with one chain.

Always check the chain requirements for the states and regions you’ll be driving through, as regulations can vary based on weather alerts and conditions.

Chain Diameter Reference Chart

Use this Chain Diameter Reference Chart to convert between trade, inch, fractional, decimal sizes and to see the chain’s pitch.

Trade Size (wire diameter): (A) is the thickness of the steel wire material used to form the chain link.

The measurement should be taken at an unbent area of the link where possible.

Pitch: (B) is the inside measurement across the length of the link.

| Trade Size | Decimal | Fraction | Metric | Pitch |

|---|---|---|---|---|

| 3.7 mm | 0.145" | 9/64" | 3.7 mm | 11 mm |

| 4.5 mm | 0.177" | 5/32" | 4.5 mm | 18 mm |

| 5.6 mm | 0.221" | 15/64" | 5.6 mm | 24 mm |

| 7 mm | 0.276" | 9/32" | 7 mm | 30 mm |

| 8.2 mm | 0.322" | 21/64" | 8.2 mm | 33 mm |

| 10 mm | 0.394" | 25/64" | 10 mm | 35 mm |

| 12 mm | 0.472" | 15/32" | 12 mm | 45 mm |

| 14 mm | 0.551" | 35/64" | 14 mm | 43 mm |

| 16 mm | 0.630" | 5/8" | 16 mm | 56 mm |

| 18 mm | 0.709" | 45/64" | 18 mm | 52 mm |

| 21 mm | 0.827" | 53/64" | 21 mm | 66 mm |

| 1/0 | 0.177" | 11/64" | 4.5 mm | 1.180" |

| 3/0 | 0.207" | 13/64" | 5.25 mm | 0.920" |

| 4/0 | 0.234" | 15/64" | 5.95 mm | 1.000" |

| 6/0 | 0.281" | 9/32" | 7.14 mm | 1.250" |

| 7/0 | 0.312" | 5/16" | 7.92 mm | 1.390" |

| 9/0 | 0.375" | 3/8" | 9.53 mm | 1.260" |

| 11/0 | 0.437" | 7/16" | 11.10 mm | 1.562" |

| 14/0 | 0.531" | 17/32" | 13.50 mm | 1.734" |