Polyester Web Sling Warnings and Instructions

Lifting & lifting systems require the use of several tools, variables & devices, and polyester web sling(s) are only one part of that system. It is critical that you read and understand this bulletin prior to using polyester web slings and the failure to do so, may result in severe INJURY or DEATH due to sling failure and/or loss of the load.

Training & Knowledge

Knowledge is acquired through training. Sling users must be knowledgeable in the safe and proper use of polyester web slings to prevent injury and death to you and others. In addition to the information found in this bulletin, polyester web sling users should also read and understand the standards and guidance provided in:

- ASME B30.9-5 Synthetic Webbing Slings: Selection, Use & Maintenance

- OSHA 29 CFR 1910.184: Slings

- OSHA Guidance On Safe Sling Use

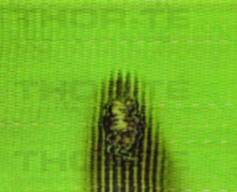

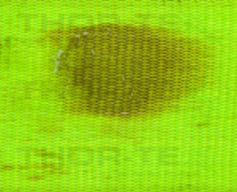

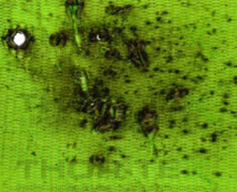

Good Inspection Practices

Because polyester web slings are made from synthetic fibers, they are vulnerable to damage in a variety of ways. Before using a sling to make a lift, it is necessary to inspect the sling for damage prior to use to prevent injury or death to you and others.Inspection requires you to LOOK & FEEL over the entire length of the sling on both sides. During inspection, should you identify any of the following conditions, the sling is to be removed from service in accordance with ASME B30.9-5.9.4.

Other removal criteria:

- Slings with fittings that are pitted, corroded, cracked, bent, twisted, gouged or broken.

- For slings with hooks sewn-in, apply removal criteria for hooks as stated in ASME B30.10.

- For other sewn-in rigging hardware, apply removal criteria as stated ASME B30.26.

- Other conditions, including visible damage, that cause doubt as to the continued use of the sling.

Polyester web slings should be inspected as follows:

- Intially—When slings are received by a qualified person to ensure there is no damage and that the sling meets the requirements for its intended use.

- Frequently—Polyester web slings should be inspected before using each shift or each day.

- Periodically—Polyester web slings are to be inspected by a qualified person, other than the person who conducts the frequent inspections.

Periodic inspections are to be done annually for normal service and monthly to quarterly for severe service. Inspection intervals are not to exceed one year. For periodic inspections, both WSTDA WS-1 and ASME B30.9 require that a written record of the inspections be maintained.

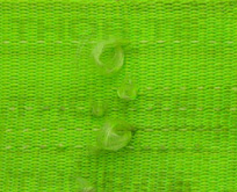

Sling Protection

To protect polyester web slings from both environmental and physical damage, avoid the following:

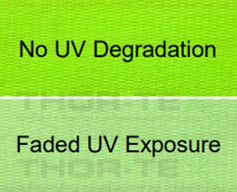

- Continuous or excessive exposure to sunlight.

- Contact with dirt or gritty type substances.

- Dragging slings on the floor, ground or rough surfaces.

- Jerking or pulling slings out from under loads.

- Twisting or tying knots in slings.

- Allowing slings to contact acids or alkalis.

- Exposing slings to temperatures above 194°F or below –40°F.

- Allowing weld spatter to land on slings.

- Allowing sling to sit on the tip of a hook instead of the base of the hook’s bowl.

- Using rigging hardware such as hooks or shackles with rough edges.

- Running or driving over slings with vehicles or mobile equipment.

To help prevent damage from sharp edges, corners and other abrasive surfaces, protective devices such as wear pads, sleeves, corner protectors and body wraps should be used. It may also be necessary to test samples to ensure protection method chosen is effective prior to lifting actual load to be lifted.

Never Exceed Rated Capacity

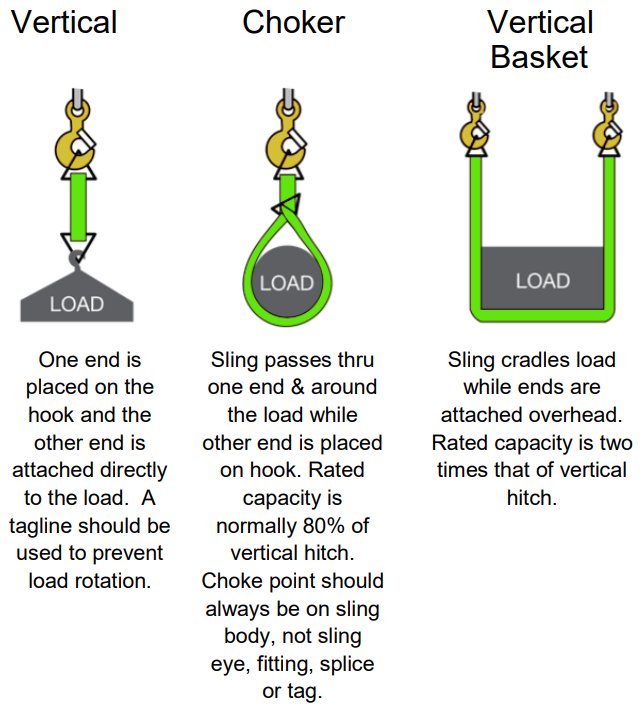

To avoid exceeding the rated capacity of a polyester web sling, a trained and qualified person must first know the weight of the load to be lifted and its center of gravity to determine if the rigging sling will be used in a vertical hitch, choker hitch or vertical basket hitch. See table below for description and illustration.

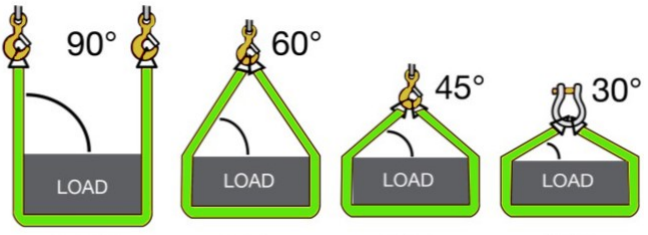

WARNING: ANGLES MATTER! For Vertical & Basket hitches, sling angles less than 90 degrees reduce the effective rated capacity of the sling. See table below.

| Angle | Sling Reduction Factor |

|---|---|

| 90° | 1.000 |

| 85° | 0.996 |

| 80° | 0.985 |

| 75° | 0.966 |

| 70° | 0.940 |

| 65° | 0.906 |

| 60° | 0.866 |

| 55° | 0.819 |

| 50° | 0.766 |

| 45° | 0.707 |

| 40° | 0.643 |

| 35° | 0.574 |

| 30° | 0.500 |

Vertical & Basket Hitches

To calculate the effective capacity of the sling, determine the angle of the sling and multiply the sling reduction factor for the determined angle times the rated Vertical or Basket capacity of the sling

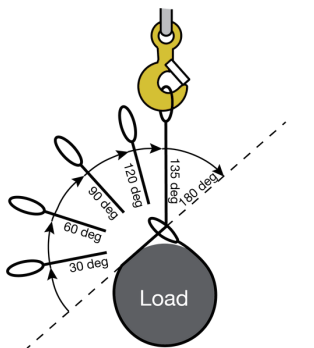

| Angle of choke | Sling Reduction Factor | |

|---|---|---|

| = or > | < | |

| 120° | 180° | 1.00 |

| 105° | 120° | 0.82 |

| 90° | 105° | 0.71 |

| 60° | 90° | 0.58 |

| 0° | 70° | 0.50 |

For Choker hitches, to calculate the effective capacity of the sling, determine the angle of choke and multiply the sling reduction factor for the determined angle of choke times the rated Choker capacity of the sling.

Stay Clear Of Load

- Never stand in the area directly beneath or near the load being lifted.

- Never stand on load being lifted.

- Never allow any part of your body to be placed between the sling and the load being lifted or between the sling and the lifting hook or rigging fitting.

- Be sure all personnel in the area of the lift are alert to the potential for the sling to become snagged during the lift.

- Never use a web sling to pull on objects in a constrained or snagged condition

Sling Storage

Knowledge is acquired through training. Sling users must be knowledgeable in the safe and proper use of polyester web slings to prevent injury and death to you and others. In addition to the information found in this bulletin, polyester web sling users should also read and understand the standards and guidance provided in:

- ASME B30.9-5 Synthetic Webbing Slings: Selection, Use & Maintenance

- OSHA 29 CFR 1910.184: Slings

- OSHA Guidance On Safe Sling Use

- Polyester web slings should always be stored in dry, dark and cool places when not being used.

- Polyester web slings should always be stored away from exposure to chemicals, high heat sources, metal turnings from machining, grinding dust, splinters, etc..

- Always be sure polyester web slings are stored in place free from dirt, oils, grime and other such materials.

- Clean only with mild soap and water. If washed, be sure polyester web sling is 100% dry before being stored. Never machine wash as it will result in loss in strength.

There are many factors that should be considered when using web slings to lift loads. Some of these factors include:

- Wind

- Visibility

- Air temperatures

- Center of Gravity

- Clear Load Path

- Sling Selection

- Lift Point

- Signals

- Weather

- Ground Stability

- Weight

- Dimensions

- Structural Stability

- Load Control

- Sling Capacity

- Planning

The information in this bulletin does not contain ALL of the information required to use web slings safely. Other recommended sources of information include:

- OSHA 29CFR 1910.184

- Web Sling Tie Down Association (WSTDA) “WS-1” Recommended Standard for Synthetic Web Slings

- ASME B30.9 Sling Standard

Web Sling Video Guides

View Our handy web sling video guides to help you choose and use polyester web slings.