Not sure which load binder to use when securing your load for transport? Discover the impressive features of ratchet binders and learn how to safely operate them for your specific needs.

Watch our video or delve deeper for further insights into the advantages of these reliable tools.

Ratchet load binders offer enhanced mechanical advantage and superior safety compared to lever load binders for securing loads. Their straightforward design, cost-effectiveness, and exceptional durability make them the preferred choice for securing heavy machinery.

At E-Rigging we carry two different types of ratchet binders, our Standard Ratchet Binder and thePeerless Ratchet Binder Plus which is of higher quality and has higher working load limits.

According to the General Cargo Securement requirements, the sum of the working load limits from all tie-downs must be at least fifty percent of the weight of the cargo.

Our Standard Ratchet Binder is powder coated red and features drop forged binder chain hooks with size and grade markings forged into the hooks.

The binder is available in two different sizes, a 9,200 lbs model and a 13,000 lbs model with working load limits that are matched to Grade 70 transport chain.

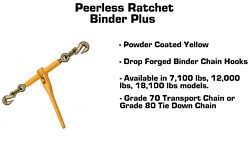

The Peerless Ratchet Binder Plus is powder coated yellow and features zinc plated drop forged binder chain hooks for greater corrosion protection.

It is available in three sizes, a 7,100 lbs model, a 12,000 lbs model, and the 18,100 lbs model which can be used with either grade 70 transport chain or Grade 80 alloy tie-down chains.

Operating a Ratchet Load Binder

Attaching the Binder

Removing the Binder

Unwrap the chain and turn the pawl to the 'out' setting.

Begin ratcheting the binder until the chain becomes slack and the binder hooks can be removed from the chain.

For a full video with more information on proper load binding techniques, please click here.

If you have any questions or want more information, please Contact Us.

Check out our Youtube channel for more helpful and informational videos.