THOR-TEX synthetic slings are an integral part of a variety of lifting jobs. They're strong, lightweight, and easy to stow. However, there are certain instances where one might be better at an application to another, so in this article we’re going to go through the pros and cons or using round slings versus web slings.

Pros and Cons to Web Slings

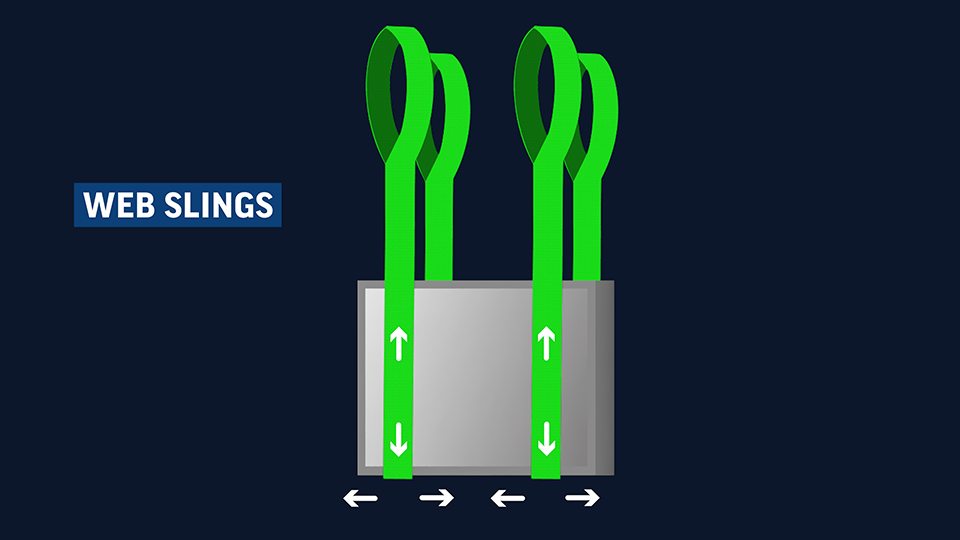

are made up of woven polyester fibers with eyes sewn into either end. These eyes come in several different configurations like reinforced eyes (bearing points lined with Cordura), twisted eyes, and flat or tapered eyes. Even though both THOR-TEX web and round slings are made of the same polyester fibers, web slings will stretch slightly more that round slings because the woven construction. They also do a great job at supporting objects from underneath, especially odd-shaped or fragile objects.In this example, the object to be moved is a piece of machinery that has fragile side panels. A web sling is great in that application since you can position the sling up underneath the machinery, without creating creases or pressure points on that machinery, dispersing the load of the machine across the width of the webbing.

A web sling might not be the best choice in instances where the sling is prone to abrasion, since every polyester fiber is exposed across the entire length of the sling. Additionally, creasing the sling through a small attachment point can cause damage, so in cases where small and permanent attachment points are present, it’s best to swap the web sling for a round sling.

Pros and Cons to Round Slings

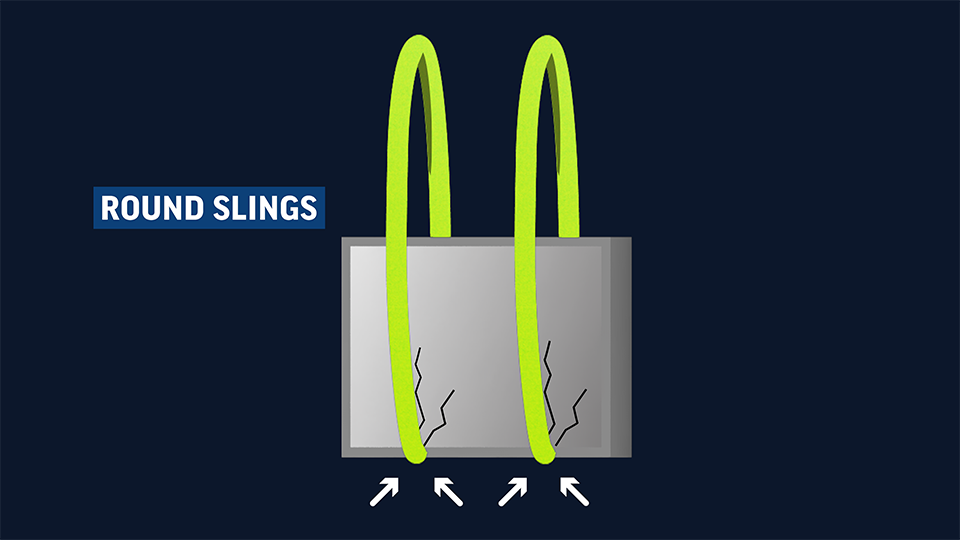

THOR-TEX Round Slings are constructed from two layers of polyester. The inner layer is comprised of continuous strands of load bearing polyester that is protected by a woven polyester jacket. This type of sling has excellent resistance to abrasion, crushing and foreign particles as well as having a low stretch factor. It’s flexibility and strength to size ratio makes it great for tight fits and small lift points.

Round slings shine in scenarios where creasing is a concern since the load-bearing polyester fibers within the outer jacket can be molded and form around various types of lift points, but especially manufacturer-designated points.

A round sling might not be the best choice in instances where a piece of machinery with no fixed lifting points and fragile corners or side panels needs to be moved. Since most of the weight is centralized to the group of polyester fibers, damage to that item may occur since there’s little-to-no distribution of weight when lifting from beneath. In these cases where an odd-shaped or fragile piece of machinery needs to be supported from underneath, its best to swap out the round sling for web sling.

For additional information on synthetic lifting slings click here.

For more information about THOR-TEX Web Slings read our safety bulletin here.

1 comment

Tom

Very nice and clear example for each sling!!