Stainless Steel vs. Galvanized Cable: Which Cable is Best for Your Project?

When selecting cable for a project, the choice between stainless steel and galvanized cable is crucial. Each type offers unique benefits and limitations depending on the environmental conditions and specific needs of your application. Here’s a straightforward comparison to help you make an informed decision.

Composition:

Stainless Steel Cable:

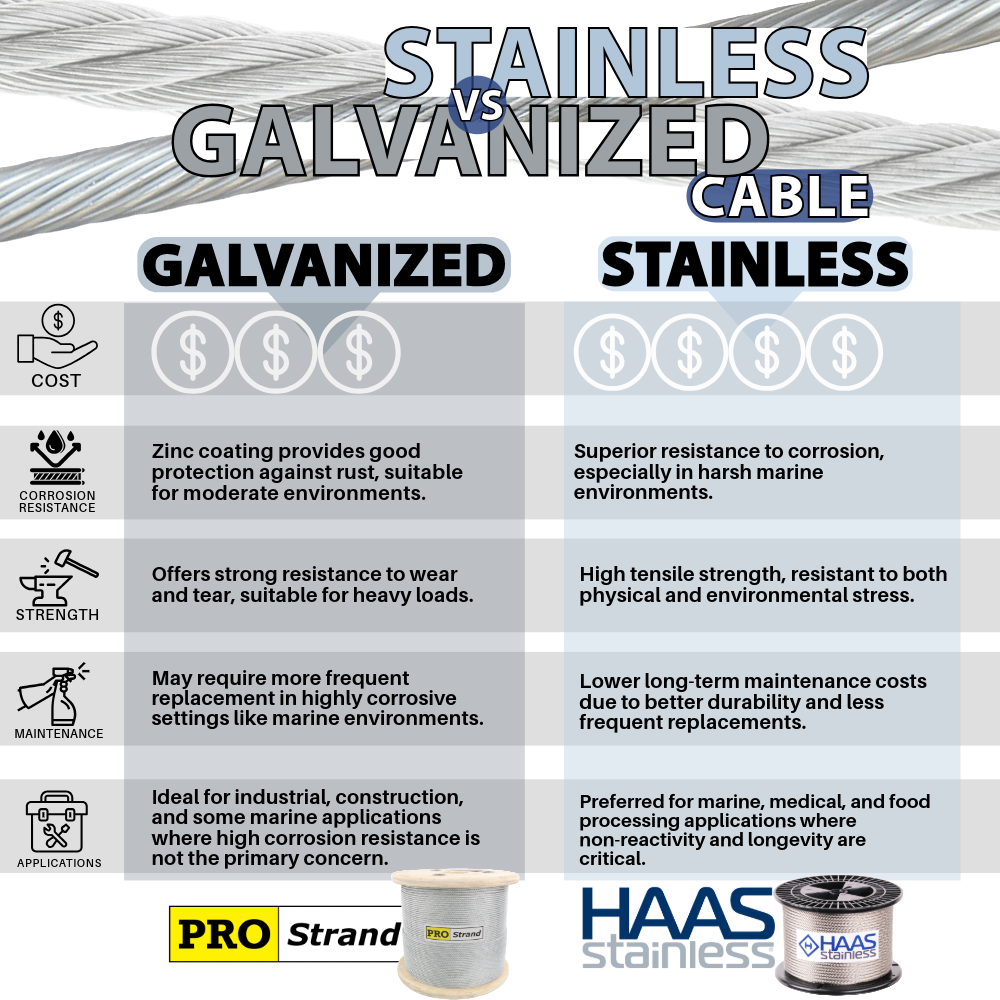

Stainless steel cable, or Stainless Steel Wire Rope, is known for its high resistance to corrosion, making it ideal for marine environments and other areas where exposure to elements is a concern. It's made from various grades of stainless steel, with 304 and 316 being the most common. Grade 316 stainless steel, in particular, includes molybdenum, which significantly enhances corrosion resistance.

Galvanized Cable:

Galvanized cable, like our Galvanized Wire Rope, is steel cable coated with a thin layer of zinc to protect against corrosion. While not as resistant to corrosion as stainless steel, it is considerably stronger and more cost-effective. It's suitable for industrial applications, agriculture, and anywhere the cable will face high physical demands but less environmental exposure.

Performance in Different Environments

Marine and Coastal Applications:

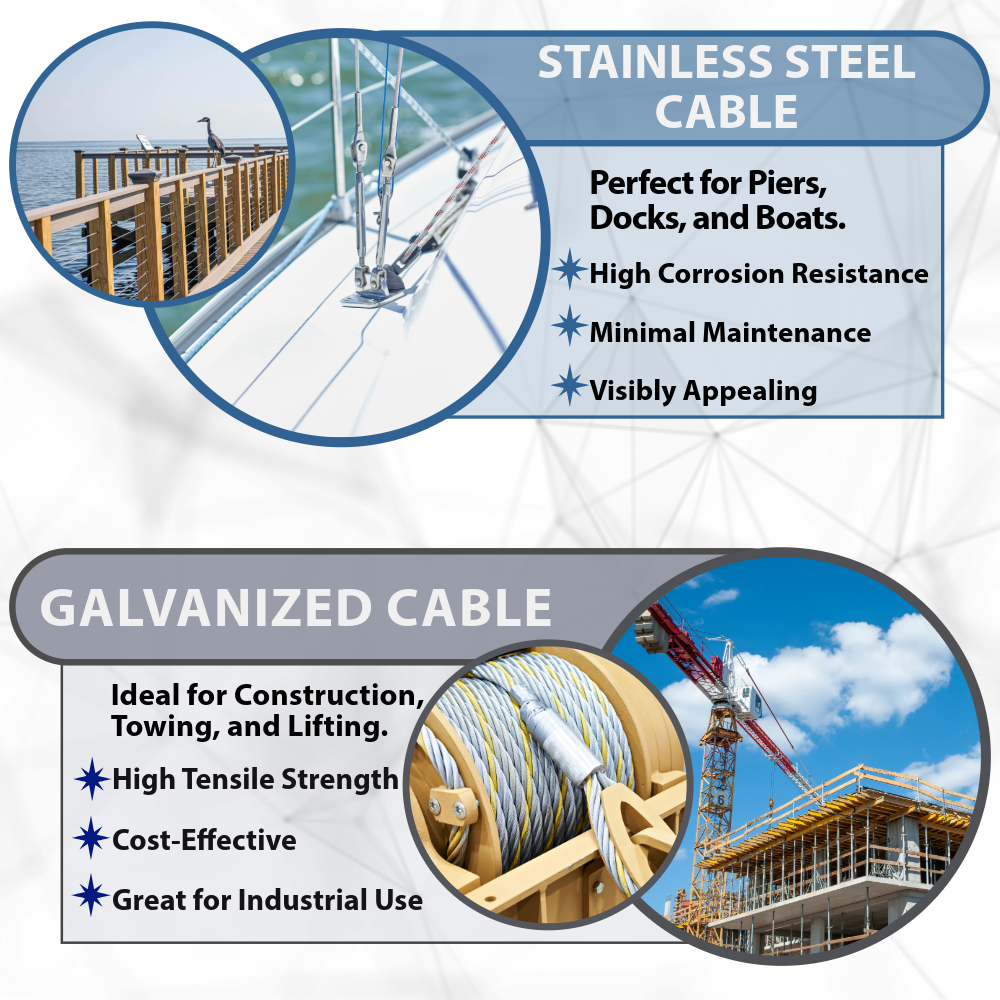

Type 316 Stainless steel cable excels in marine settings. Its ability to resist salt water and humidity prevents rust, ensuring longevity and durability. For piers, docks, or sailboat rigging, stainless steel is typically the preferred choice. It is also commonly used for cable railing both indoors and outdoors.

Industrial and Outdoor Environments:

Galvanized cable is often used in outdoor and industrial settings where the cable is subjected to mechanical stress. Its superior strength and lower cost make it a practical choice for heavy-duty tasks such as towing, lifting, and securing loads in construction.

Maintenance and Longevity

Stainless Steel Cable:

This type requires minimal maintenance, thanks to its corrosion-resistant properties. It remains durable and maintains its appearance over time, which is essential for visible applications like stair railings or architectural designs.

Galvanized Cable:

While galvanized cable can last a long time, it may require more frequent checks and replacement in corrosive environments. The zinc coating can wear off, exposing the underlying steel to rust.

Cost Considerations

Initial costs for stainless steel cable are higher, reflecting its durability and specialized properties. However, for projects where long-term reliability in corrosive environments is necessary, the investment can be justified.

Galvanized cable is more budget-friendly and offers high tensile strength. For short-term projects or those in less corrosive environments, it provides excellent value.

Choosing between stainless steel and galvanized cable depends on your project’s specific requirements. Consider environmental exposure, mechanical demands, budget, and longevity when making your decision. Always check the working load limit before use and inspect your cable often for damage. If you have any questions on what kind of cable to choose for your project, we’re here to help!