Metal post cable railing systems are just as popular as wood post systems and the REVO system that we manufacture here at HAAS Stainless is what you're going to be using for your metal post cable railing system. So first let's talk about the post dimensions and hole sizes that you'll need to take into consideration when installing REVO Standard and Low-profile End Stops in metal posts.

REVO thru-post end stops can be installed in metal posts ranging in size from a 1 1/2” to 4” in diameter. This demonstration frame is constructed of 2”x2” steel intermediate and termination posts.

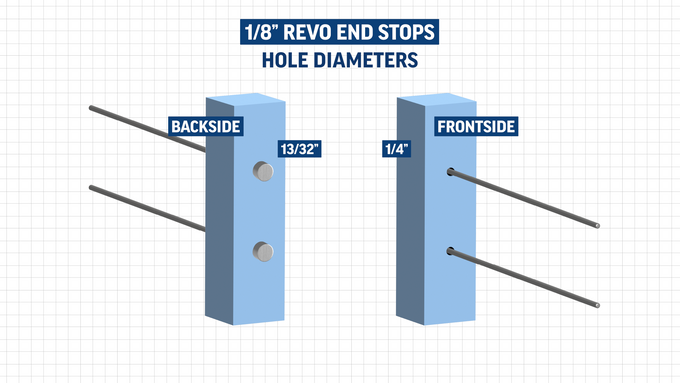

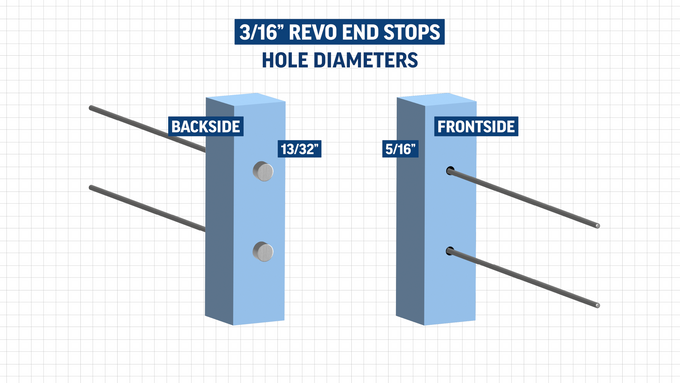

Whether you're ordering prefabricated posts like we did, or if you're going to be constructing the posts yourself, you want to make sure that you're drilling the correct hole sizes for your REVO system components. For 1/8” REVO end stops, you will need to drill a 13/32” hole on the back sides of your termination post and 1/4” hole on the front side of your termination post. For 3/16” REVO end stops, you will need to drill a 13/32” hole on the backside of your termination post and a 5/16” hole on the front side of your termination post.

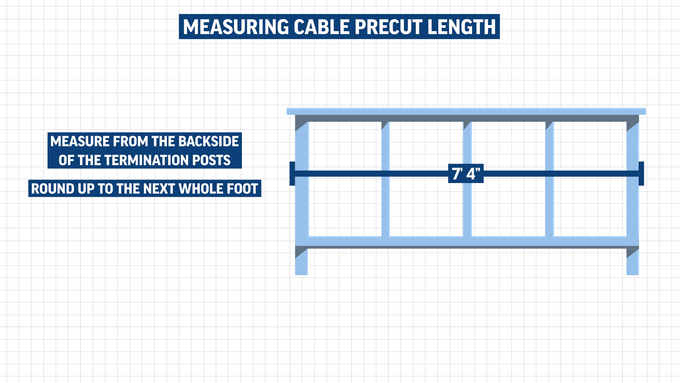

Once the holes in your post have been drilled, the next step will be to precut your cables for your cable run. Start off by taking a measurement from the backside of your termination posts and then round that measurement up to the next foot. This will ensure that you have enough cable length to install your thru-post tensioner at the opposite end of your run.

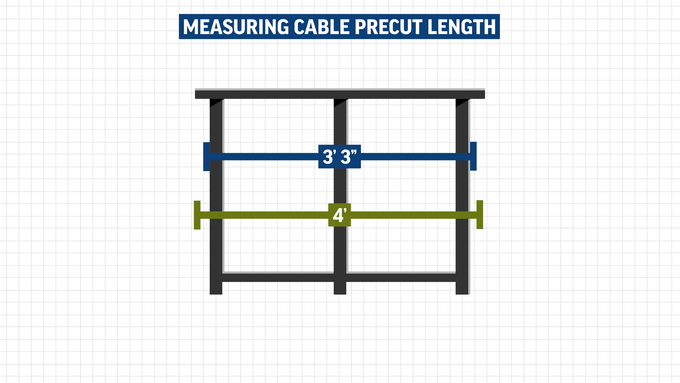

Our frame ended up measuring 3’3” long from one termination post to the other, so we will be precutting all seven of our cables at 4’.

Go ahead and precut the amount of cables you’ll need for the runs you’re installing.

Once all the cables have been precut, slide on either your standard or low-profile end stops onto the end of each cable for the run. Grab your Crenshaw Swaging tool and then swage your end stops onto your cable.If you're not familiar with the swaging process, head over to our video all about how to swage HAAS Stainless REVO Cable Railing components.

Once all your stops for the run have been swaged on to your cables, feed each cable through the backside of your termination post and make sure that the end stops seat properly in their respective holes. Lastly, feed your cable through any of the intermediate posts in your run.