There are four main styles of

eye bolts available

in a variety of sizes and finishes:

These fittings are made up of a threaded shank with a loop or eye at one

end. The eye bolt is inserted through a hole and secured on the back side

with a nut. Regular eye bolts have a working load limit which should be

taken into consideration when used for lifting or supporting an overhead

load. They are designed for straight line loading only and can bend or

break if loaded at angles.

Shoulder eye bolts have a supporting shoulder that allows them to be

loaded at slight angles, if properly installed. These fittings are very

versatile and are designed to be inserted through a hole and secured on

the back side with the provided nut. Its working load limit should be

taken into consideration when used for lifting or supporting an overhead

load.

Lag eye bolts have threads designed to screw into wood. They don’t have

a working load limit because their strength is dependent on the species

and condition of the wood it is screwed into. For example: A lag eye

bolt will hold more load when screwed into a new oak board, compared to

an old pine fence post.

Machinery eye bolts are often used to screw into pieces of equipment to

serve as a lifting point. They have short, fully threaded shanks that are

designed to be screwed directly into threaded or tapped holes. These

fittings have a shoulder allowing for lifting at slight angles, and a

listed working load limit.

The size designation for eye bolts are common across all types.

This is a ½” x 6" shoulder eye bolt and a ½” x 6" Stainless steel lag eye

bolt.

The ½” measurement references the diameter of the shank.

The 6” measurement refers to the length of the shank.

The larger the diameter of the shank, the larger the working load limit. A

longer shank length allows you to go through thicker objects. The threaded

portion varies for each eye bolt, so visit our website if you need more

detailed dimensions of our eye bolts.

Strength and Durability from Different Manufacturing Methods

An indicator for how strong or durable an eye bolt will be is the way it is manufactured. Eyebolts are manufactured in a variety of ways to suit users' needs for cost and durability. Always refer to the working load limit first when determining an eyebolt's suitability for your application. Drop forged or cast eyes are recommended for critical applications. These are manufacturing methods in order of least durable to most durable.

Formed

Formed eyebolts are the most cost-effective types and are made by bending a straight rod into an eyebolt shape.

Formed and Welded

The same process as a formed eyebolt, but the bent eye is welded shut for added strength and durability.

Cast Steel

These eyebolts are a cost-effective stainless steel option and have precision cast eyelets with welded threaded shanks.

Drop Forged

The most durable of all eyebolt types, these are drop forged into their shape from superheated steel. This process provides the strongest grain structure inside the steel and a continuous connection between the eye and the shank.

We offer our eye bolts in stainless steel, hot dipped galvanized steel, and

self-colored finishes.

Stainless Steel is the

most corrosion resistant and has the best-looking finish.

Angular Loading

Oftentimes, loads are applied to eye bolts at an angle and for these types

of applications shoulder eye bolts should only be used.

Loading at an angle can alter the working load limit of the eye bolt.

It is important to note that all eye bolts are designed for loading with the

axis at the center of the eye. They should never be loaded perpendicular to

that axis because they are likely to bend and break.

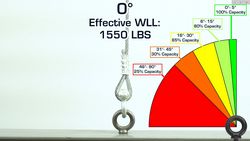

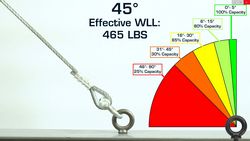

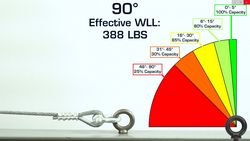

Eye Bolt Working Load Limit Effects

due to Angular Loading

The degree of angle of your load can have a big effect on the working load

limit of the eye bolt.

This cable is at 0 degrees. At 0 to 5 degrees, the eye bolt is rated at 100

percent of its working load limit. In this case, the catalog working load

limit of this 3/8th inch eye bolt is 1,550 pounds.

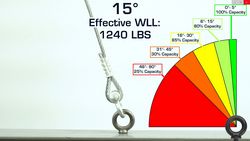

At 15 degrees, the working load limit is reduced by 20% and the effective

working load limit of the eye bolt becomes 1240 pounds, which is 80% of the

original rated capacity.

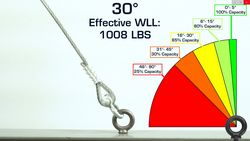

30 degrees makes for 65% of the original rated capacity.

45 degrees makes for 30% of the original rated capacity.

90 degrees makes for 25 % of the original rated capacity. The 75% reduction

in capacity makes the effective working load limit only 388 lbs.

Because of the effect that angles have on eye bolts and working load limits,

we recommend using swivel hoist rings as an alternative choice. The

advantage to them over eye bolts is that they maintain 100 percent of the

working load limit at any angle from 0 to 90 degrees.

First, determine thickness of what the eye bolt will be going through.

Then, choose an eye bolt with a shank long enough so that the threads

protrude on the back side and allow the nut to be tightened properly.

If the unthreaded portion of the shank protrudes below the bottom surface

and does not allow the nut to be tightened, you can use washers to fill the

space of the unthreaded portion of the shank.

Machinery eye bolts are primarily intended to be installed into tapped

holes. The eye bolts are threaded to UNC standard and the hole needs to be

tapped accordingly to ensure the shoulder will be firmly seated against the

object to be lifted.

When drilling and tapping the hole for the eye bolt, the hole depth should

be the length of the shank plus one half the diameter of the shank.

As mentioned earlier, eye bolts are to be used so that loads are applied

about the axis of the eye.

When installing machinery eye bolts it may be necessary to add washers to

shim the eye bolt to achieve the correct alignment.

We will illustrate this by attaching 4 machinery eye bolts to each corner of

this lifting box. Note that all the eye bolts are NOT “in line.”

To correct this, we are going to add washers as needed to get the eye bolts

into the “in line” position as shown here.

General Safety Precautions

When selecting an eye bolt, it is important to consider the following

factors:

-

The load capacity: The eye bolt must be able to

support the weight of the load it will be lifting.

-

The material of the eye bolt: The eye bolt must be

made of a material that is strong enough to support the load and that is

compatible with the material it will be attached to.

-

The type of attachment: The eye bolt must be able

to be attached to the material it will be used with.

Load Capacity

The load capacity of an eye bolt is

determined by its size and material. The larger the eye bolt, the more

weight it can support. The material of the eye bolt also affects its load

capacity. For example, a steel eye bolt can support more weight than an

aluminum eye bolt of the same size.

Material

The material of the eye bolt matters

because it must be strong enough to support the load and that its

compatible with the material it'll be attached to. Ex: a steel eye bolt

should not be used to attach to a wooden structure.

Type of Attachment

The type of attachment is

important because the eye bolt must be able to be attached to the material

it'll be used with. Ex: an eye bolt with a threaded shank can be screwed

into a threaded hole, while an eye bolt with a plain shank can be attached

with a nut.

Working Load Limit (WLL)

the WLL of an eye bolt is

the maximum amount of weight it can safely support. It's important to

always check the WLL of an eye bolt before using it. The WLL is typically

stamped onto the eye bolt.

Safety

Use eye bolts in a safe and responsible

manner. Here are some safety tips:

-

Always make sure the eye bolt is properly sized for the load you'll be

lifting.

- Use a wrench to tighten the nut on the eye bolt.

- Do not overload the eye bolt.

- Do not load the eye bolt at an angle.

Never rig or reeve a sling or cable from one eye bolt to the other as shown

here.

We hope this video has helped you with the selection and installation of

eye bolts for your rigging assembly. If you have any further questions,

please Contact Us.

Please Subscribe to our

YouTube Channel

for more information on various rigging topics.