How to Select and Install Eye Bolts

Used as a lifting or securement point, rigging eye bolts are some of the most commonly used rigging fittings. Similar to all rigging fittings, the application determines which of the various types to use.

The four basic types are regular eye bolts, shoulder eye bolts, screw eye bolts, and machinery eye bolts . All four of these basic types of heavy duty eye bolts that E-Rigging offers are manufactured in the drop forged process to ensure greater strength.

Regular and shoulder rigging eye bolts are essentially the exact same part with the only obvious exception being the shoulder. The shoulder feature provides more stability to the base of the eye and therefore, makes it the recommended choice for angular loading. Regular eye bolts are not recommended for angular loading. Both regular and shoulder eye bolts have UNC type threads.

Screw eye bolts are designed for screwing into wood. And because of this, do not have a working load limit assigned to them because it is not possible to determine the various densities and conditions of the wood the eye bolts are screwed into.

Machinery eye bolts are designed with a shoulder and are designed for angular loading. The difference between machinery eye bolts and regular and shoulder type eye bolts is that the shank and threads of the machinery eye bolt do not protrude through the base metal. Therefore, all of the holding strength of the machinery eye bolt is on the threads. Regular, shoulder and screw eye bolts have a hot dip galvanized finish and the machinery eye bolts are self-colored with a light rust preventative oil applied.

To learn more about the heavy duty eye bolts we have for sale, browse our online catalog above! If you are unsure what product may work best for your specific job, check out our Ultimate Guide to Eyebolts or feel free to contact us. We are happy to help you find the perfect solution!

More information on Eye Bolts and Eye Nuts

How should you select the right bolt?

Eye bolts are marked with their thread size NOT with their rated capacities. Make sure you select the correct eyebolt based on its type and capacity for the lift you are conducting.

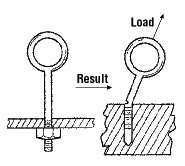

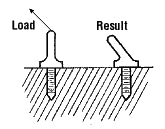

- Use plain or regular eye bolts (non-shoulder) or ring bolts for vertical loading only. Angle loading on non-shoulder bolts will bend or break them.

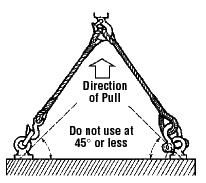

- Use shoulder eye bolts for vertical or angle loading. Be aware that lifting eye bolts at an angle reduces the safe load.

- Follow the manufacturer's recommended method for angle loading.

Incorrect use of shoulder bolt

Shoulder eye bolt with load correctly applied

Incorrect way of applying angle load

How should you use eye bolts safely?

- Orient the eye bolt in line with the slings. If the load is applied sideways, the eye bolt may bend.

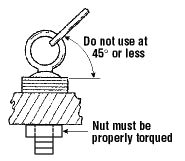

- Pack washers between the shoulder and the load surface to ensure that the eye bolt firmly contacts the surface. Ensure that the nut is properly torqued.

- Engage at least 90% of threads in a receiving hole when using shims or washers.

- Attach only one sling leg to each eye bolt.

- Inspect and clean the eye bolt threads and the hole.

- Screw the eye bolt on all the way down and properly seat.

- Ensure the tapped hole for a screw eye bolt (body bolts) has a minimum depth of one-and-a-half times the bolt diameter.

- Install the shoulder at right angles to the axis of the hole. The shoulder should be in full contact with the surface of the object being lifted.

- Use a spreader bar with regular (non-shoulder) eye bolts to keep the lift angle at 90° to the horizontal.

- Use eye bolts at a horizontal angle greater than 45°. Sling strength at 45° is 71% of vertical sling capacity. Eye bolt strength at 45° horizontal angle drops down to 30% of vertical lifting capacity.

- Use a swivel hoist ring for angled lifts. The swivel hoist ring will adjust to any sling angle by rotating around the bolt and the hoisting eye pivots 180°.

What should you avoid when using eye bolts?

- Do not run a sling through a pair of eye bolts: this will reduce the effective angle of lift and will put more strain on the rigging.

- Do not force the slings through eye bolts. This force may alter the load and the angle of loading.

- Do not use eye bolts that have been ground, machined or stamped.

- Do not use bars, grips or wrenches to tighten eye bolts.

- Do not paint an eye bolt. The paint could cover up flaws.

- Do not force hooks or other fittings into the eye; they must fit freely.

- Do not shock load eye bolts.

- Do not use a single eye bolt to lift a load that is free to rotate.

- Do not use eye bolts that have worn threads or other flaws.

- Do not insert the point of a hook in an eye bolt. Use a shackle.