What type of soft rope should I be using for my application? Great question! there's a lot of different types of soft rope out there, so in this blog we're going to go through rope fiber-type and rope construction to help you make the best choice for your application.

We specialize in providing all types of rope and rope accessories, so don’t forget to check out our collection of soft ropes.

Manila Rope

Manila rope was once the preferred choice in ropes before synthetic fibers were developed. Manila ropes still maintain some advantages to synthetic fibers. It is not affected by heat and has an excellent resistance to the sun's UV (Ultraviolet) rays. Manila rope has low stretch and good abrasion resistance, but poor chemical resistance and is subject to rot.

Nylon Rope

Nylon Rope is known for its elasticity and tremendous shock absorbing qualities. It has good abrasion resistance, is rot proof, resists oil, gasoline, and most chemicals. It has good resistance to UV rays.

Polypropylene Rope

Polypropylene, or Polypro rope is a great economical choice and has excellent resistance to most common chemicals. It is also resistant to rot, mildew, and deterioration. It has good abrasion resistance, good strength, and moderate stretch. It’s used in many marine applications since it will float.

Polyester Rope

Polyester rope is high strength, low stretch, torque free, excellent wet/dry abrasion resistant and wet/dry strength with good resistance to ultraviolet rays and common chemicals. Polyester rope obtains the best weathering characteristics of all popular fibers. Polyester stretches less than nylon, so it does not have the elasticity of shock absorbing qualities that nylon does. It is very popular as a marine or industrial rope where stretch is not desired.

Ultra-High Molecular Weight Polyethylene

Ultra-High Molecular Weight Polyethylene (UHMWPE) Rope is often referred to as the brand name, Dyneema®. This rope has very low stretch and superior wear resistance. Has very low torque, excellent UV protection, and is acid/alkali resistant. Our Sea-StrandX UHMWPE rope come in 12-strand Hollow Braid, making it easy to inspect since all the strands are visible and damaged strands turn lighter in color. UHMWPE rope is comparable in strength to steel wire rope but weighs less and is flexible and easy to store.

Rope Construction

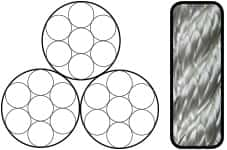

Twisted Rope

Twisted, or Laid rope is the earliest form of rope dating all the back to 4000 B.C. Most twisted rope consists of three strands and is usually “right laid”. Rope makers take two to four twisted strands and twist them in the opposite direction to create a strong rope that is still used in various industries and hobbies today. One of the drawbacks of this construction is that every fiber is exposed to abrasion numerous times along the length of the rope. This means that the rope can degrade to a number of inch-long fiber fragments, which is not easily detected visually. However, twisted rope is usually stronger than braided cord of the same size because its fibers are always parallel to each other.

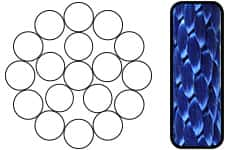

Double Braided Rope

Double braided rope is simply a diamond-braided rope with another diamond-braided rope woven over it. The over-braid may be made of the same or different fiber as the diamond braided rope core. This rope typically has good strength and abrasion resistance since the outer core protects the inner core while both are load bearing. The double braids do however make it difficult to splice.

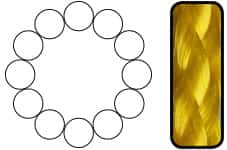

Solid Braided Rope

In solid braided rope, the strands all travel the same direction, clockwise or counterclockwise, and alternate between forming the outside of the rope and the interior of the rope. As a locked stitch constructed rope with a smooth appearance and small vertical picks, it is extremely strong and cannot be unraveled, even when cut. It's important to note that solid braid ropes can be easily knotted but they cannot be spliced. They're used for general purpose applications especially animal leads.

Hollow Braided Rope

hollow braid rope is a single diamond braided cord that's constructed of 8, 12, or 16 strands and it's usually made in either nylon, polypropylene, or UHMWPE. Hollow braided rope is the same as the Double Braided rope without the core. Because it does not have a core, it’s very flexible and simple to splice. Hollow braided rope is constructed like Chinese finger traps, with half of the strands going clockwise and the other half going counterclockwise. The strands can interlock under load and can be useful in towing, sailing and mooring, and even general applications.

Eight-Plait Rope

Eight-plait rope is constructed by intertwining four sets of two strands in a maypole fashion around the rope axis in a plain pattern: one over and one under. It handles like Twisted/Laid rope and has the same tensile strength, but it's more absorbent which makes it great for anchor rodes. Note that Eight-Plait should be submersed for 1-hour prior to load bearing in marine applications.

Need more information on soft rope? Check out our Rope Comparison Chart Rope Diameter Tolerances, Nylon and Polypropylene Specifications, and our Rope Strength Guide.

1 comment

Carolyn Cooney

Thank you for the interesting guide to rope. I am looking for a rope for a nature walk to be used between wood posts to form a guide for visually impaired persons. I am wondering what your recommendation would be. I would hope the rope would be comfortable to the touch, not scratchy.