Watch this helpful how-to video on our thimble offerings!

Keep reading for more information.

Thimbles are used to protect the eyes of cable and rope slings from abrasion by providing a solid steel barrier between the fragile cable strands and the other rigging fitting used in the connection. Thimbles also prevent eye deformation or kinking by giving structure to the cable eye. After repeated high load use, wear and kinking can reduce the strength of the cable and can lead to premature failure.

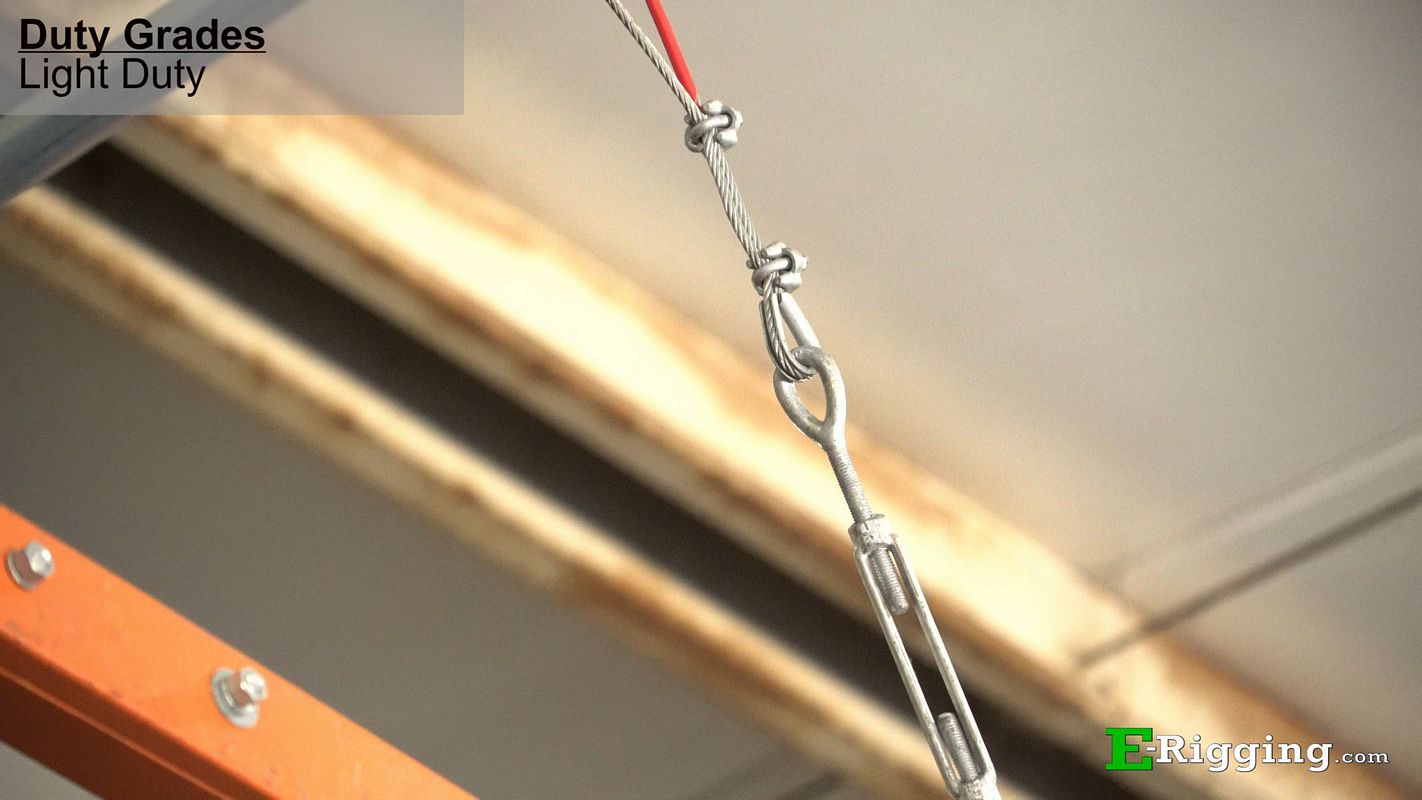

Thimbles come in two different duty grades, Light Duty and Heavy Duty.

Light duty thimbles are typically used in static applications such as a permanent installation, a controlled environment, or in situations where they won’t experience much load.

Light duty thimbles typically work best on traditional fiber rope because they can handle the same amount of load and rough handling as you would expect a fiber rope to take. You can see here that this light duty thimble is ideal for this application, while this heavy-duty thimble is grossly oversized.

Because heavy duty thimbles have extended protective material around their edges, and a tendency to resist deformation in uncontrolled applications, they are commonly used in applications that will experience dynamic loading or loads near or at the working load limit. Heavy duty thimbles are ideal for lifting, towing, and applications that will require the user to frequently connect and disconnect the thimble to other rigging components.

When choosing a thimble for your application, it’s important to consider what type of environment the thimble will be used in. E-Rigging offers thimbles that are made from Zinc Plated Steel, Hot Dipped Galvanized Steel, and Type 316 Stainless Steel.

Starting with the most corrosion resistant, stainless-steel thimbles are best suited for being used in outdoor applications and are highly resistant to rust. Stainless Steel thimbles are also ideal for being used in or near saltwater environments where corrosion frequently occurs and are the best choice when using stainless steel cable or chain.

Our heavy duty, hot dipped galvanized thimbles come in at a lower cost than stainless steel and are also suited for outdoor environments. While galvanized components are also ideal for outdoor use, galvanized components can exhibit signs of surface rust if the galvanized coating is worn off on the load bearing or contact areas of the component, this type of surface rust is normally worn off when loaded or used and shouldn’t affect the component’s performance.

Our light duty zinc plated thimbles can also be used outdoors, but it’s important to be aware that a zinc coating is thinner than a hot dipped galvanized coating, so the thimble may exhibit signs of rust earlier than a hot dipped galvanized thimble, this is especially true in environments where the thimble will be exposed to rain or snow, or in salt air or salt water environments.

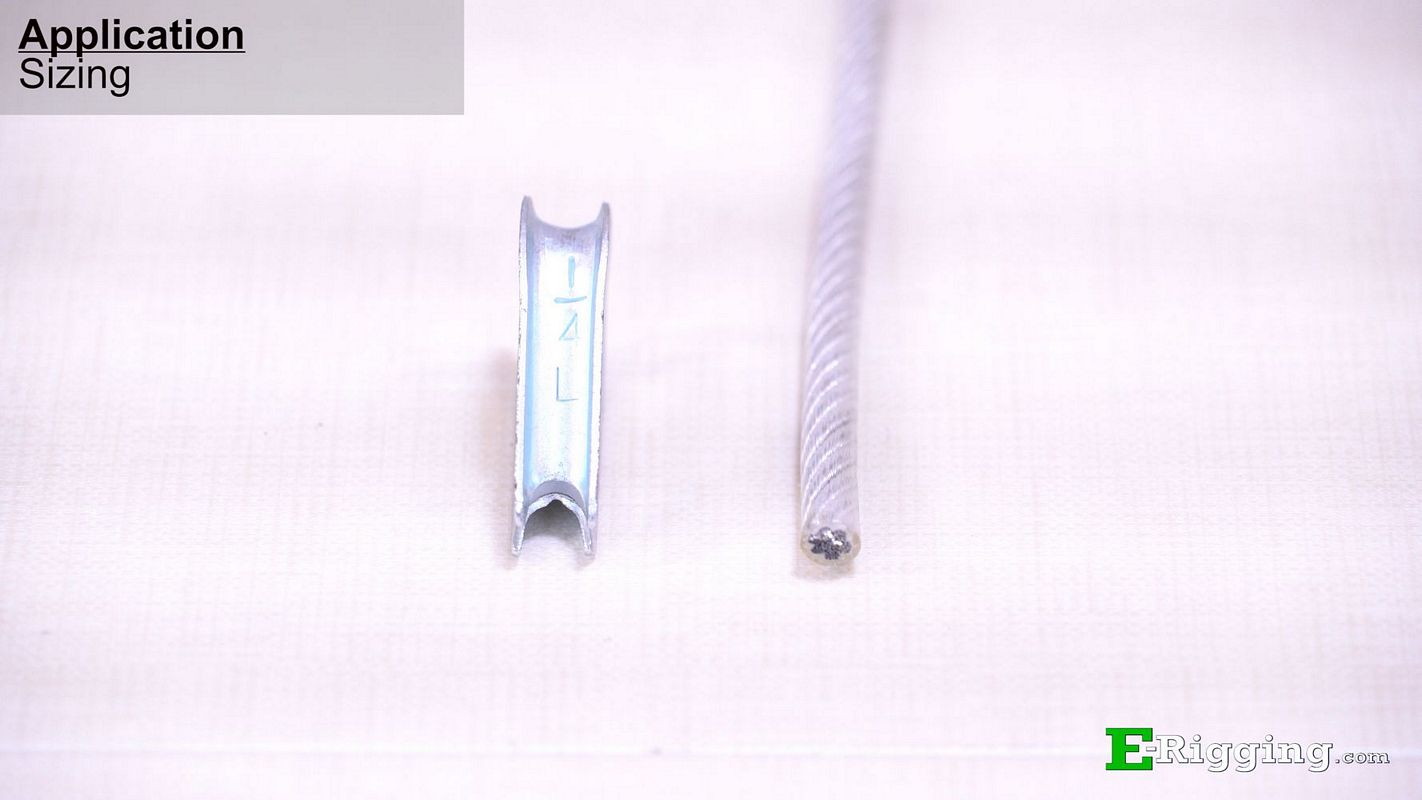

Thimbles can be used in conjunction with cable and rope to form rigging assemblies. The most important thing to consider when doing so, is making sure that the thimble is sized properly and securely fastened in the eye of the cable that is being used. If the thimble is too loose in the eye, it can fall out or rotate, and if it is undersized or grossly oversized, connections to other properly sized rigging fittings can become difficult.

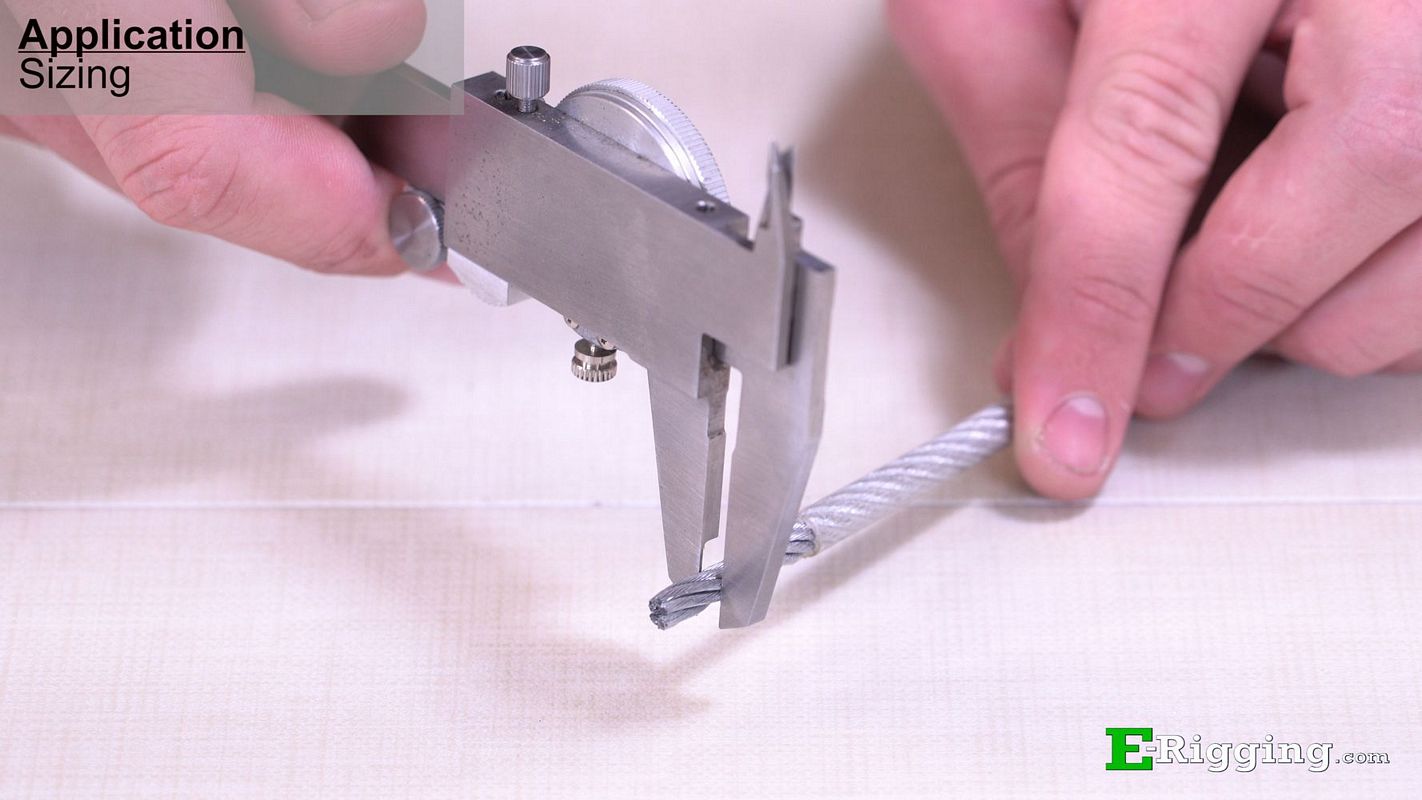

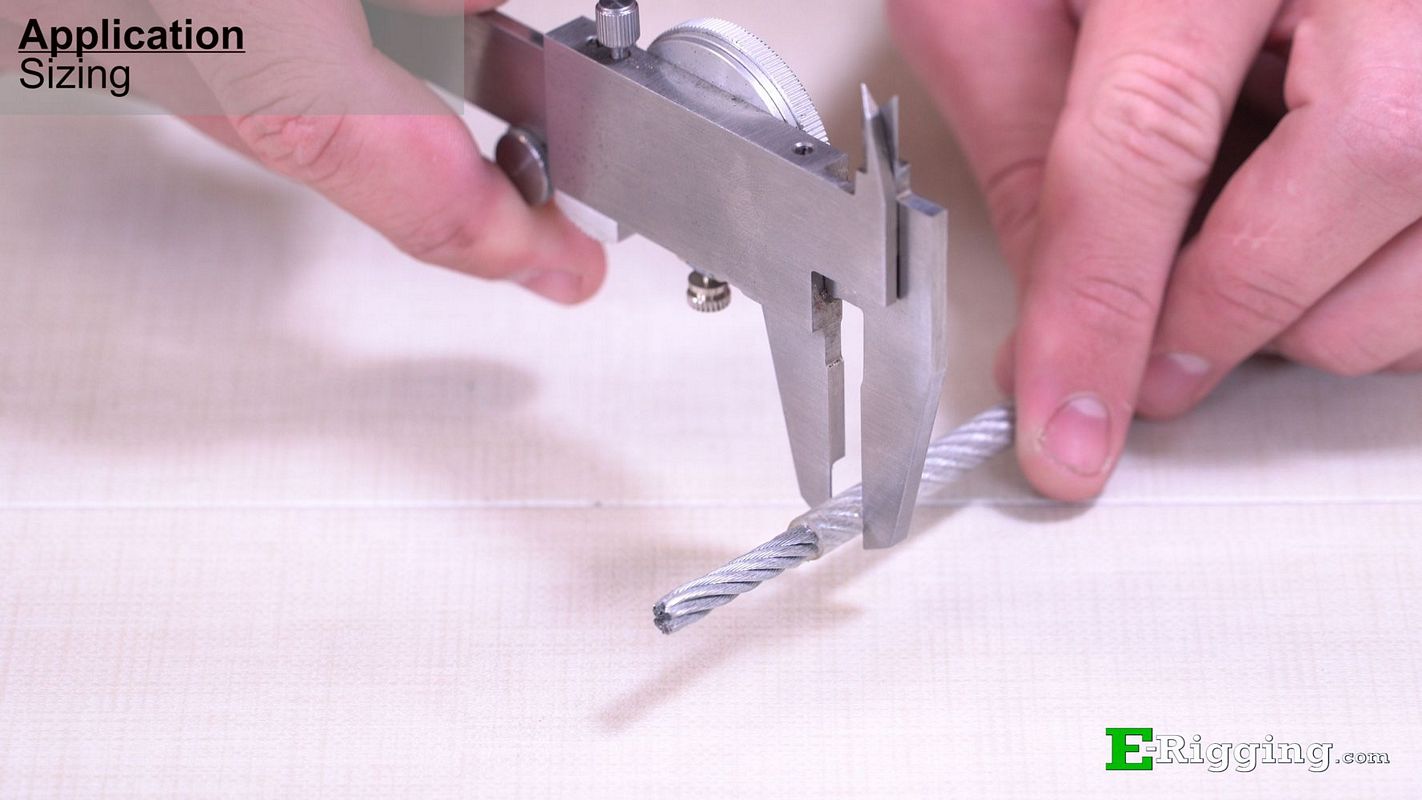

When sizing the thimble to cable, it’s important to size the thimble to the actual size of the cable that you are using with it. For example, if you are using 1/4" uncoated cable, use a 1/4" thimble.

The size of vinyl coated cable can be confusing because some manufactures measure different vinyl coated cable diameters. E-Rigging lists vinyl coated cable by the cable diameter, so the vinyl coating diameter adds a little thickness. The finished or final cable diameter is listed on the product pages of E-Rigging’s website. It typically coincides with the next size larger thimble. For example, if you are using 3/16" vinyl coated cable that is coated to 1/4" diameter, you’d want to use a 1/4" thimble.

When using stripped vinyl coated cable, you are going to want to size it just like uncoated cable. So, if you are using 3/16" x 1/4" vinyl coated cable, use a 3/16" thimble.

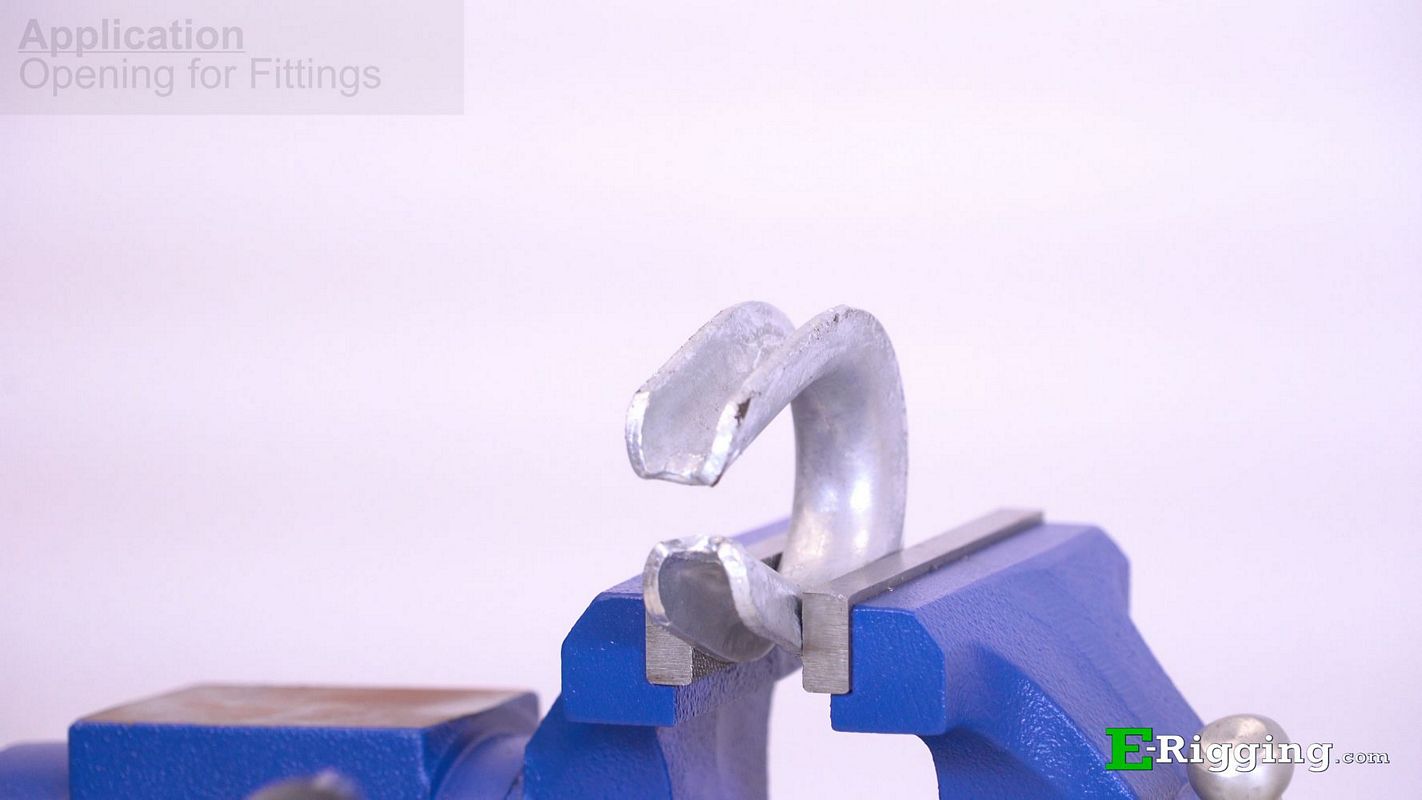

Thimbles are often used with other rigging components with a solid eye, and must be opened to do so. You can use a set of pliers to hold onto each side of the thimble, and with a twisting motion, open the thimble so that the component can be inserted into the thimble and then return the thimble to its normal shape.

The same process can also be done by hand if the thimble is small enough.

Some thimbles cannot be bent by using a pair of pliers or your hands, so for larger thimbles, a vise and pipe is the preferred method.

For more information and technical resources, Click Here to be redirected to our resources page.