Manila Rope

Manila rope was once the preferred choice in ropes before synthetic fibers were developed. Manila ropes still maintain some advantages to synthetic fibers. It is not affected by heat, and has an excellent resistance to the sun's UV (Ultraviolet) rays. Manila rope has low stretch and good abrasion resistance, but poor chemical resistance, subject to rot.

E-Rigging.com has a large selection of 3-Strand Twisted Manila Rope in lengths up to and including 1200 feet.

Manila rope, made from natural fibers, offers advantages over synthetic ropes, such as resistance to heat and UV rays, low stretch, and good abrasion resistance. Ideal for construction, marine, and landscaping projects, it provides a sturdy and eco-friendly option. However, it has poor chemical resistance and is subject to rot. E-Rigging.com features a wide selection of 3-strand twisted Manila rope, available in lengths up to 1200 feet. Perfect for heavy-duty applications, explore our top-rated Manila ropes to find the best fit for your needs.

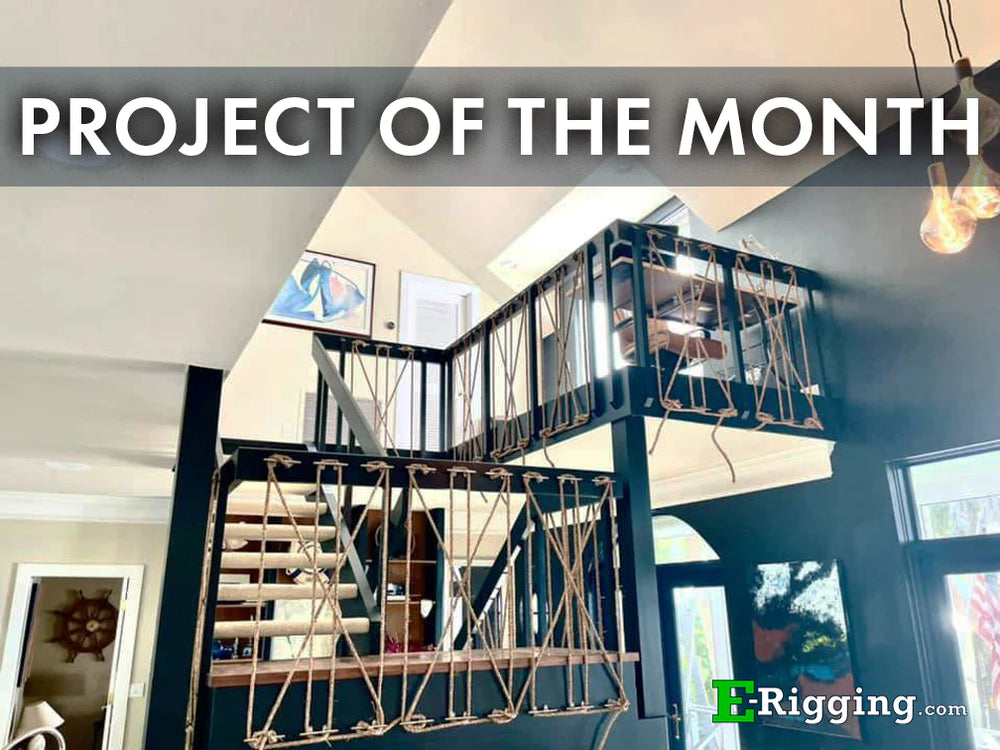

Featured Project Blogs on Manila Rope

Featured Videos on Manila Rope

Manila Rope FAQs

Manila rope is widely used in landscaping for creating natural garden features, in construction for scaffolding and securing materials, and in marine applications for mooring and towing. It is also popular for decorative projects due to its rustic look and is often used in outdoor activities like camps and adventure parks. Its strength and natural resistance to UV rays make it ideal for various practical applications.

Another name for Manila rope is hemp rope. This natural fiber rope is valued for its strength and durability, making it suitable for both heavy-duty and decorative uses. The term "hemp rope" is often used interchangeably with Manila rope due to their similar natural properties.

Manila rope is not as strong as nylon rope; nylon rope has higher tensile strength and better resistance to elements like moisture and chemicals. However, Manila rope is preferred for applications requiring a natural look and eco-friendliness, such as landscaping and decorative projects. Despite its lower strength, Manila rope offers good abrasion resistance and low stretch.

Manila rope is made from the fibers of the abaca plant, a species of banana native to the Philippines. The process involves harvesting the plant, extracting the fibers, and then drying and combing them to ensure uniformity. The fibers are then spun into yarns, which are twisted together to form the rope. This traditional method ensures the rope retains its natural strength and durability.

Manila rope is made out of the natural fibers of the abaca plant, known for its strength and durability. These fibers are harvested, processed, and spun into yarns before being twisted into the final rope. The use of abaca fibers gives Manila rope its distinct characteristics, such as resistance to UV rays and heat, making it suitable for various applications.

To keep Manila rope from fraying, you can apply tape, such as electrical or duct tape, around the ends of the rope before cutting it. Another method is to whip the ends with string or twine, wrapping tightly to secure the fibers. Additionally, you can dip the ends in liquid rubber or a similar sealant to bind the fibers together. These techniques help maintain the rope's integrity and prolong its lifespan.

For more information, visit our Rope collection page:

Back to top