Eye bolts are an important part of many lifting and suspension assemblies. While many rigging professionals use them for in-line loading, they’re commonly used for angular loading as well. In this blog, we’ll be showing you best eye bolt installation practices and eye bolt load capacity reductions for different angles of operation.

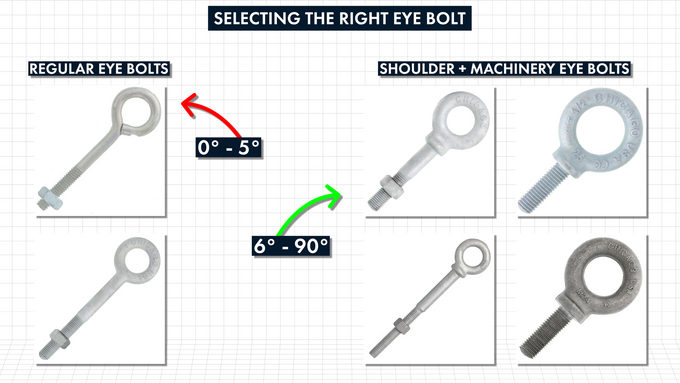

Selecting the Right Eyebolt for Angular Loads

For any load angled at 6-degrees or more, you’ll want to choose a shoulder or machinery eye bolt, since regular eye bolts are only rated for working loads that are aligned within 5 degrees from the eye bolt’s centerline.

Eye bolts should be properly installed so that they operate reliably and safely under angular loads. For more information on how to properly install eye bolts, check out Eye Bolt Guide here.

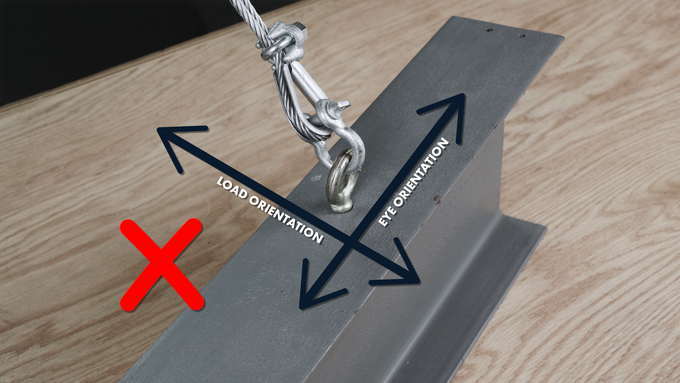

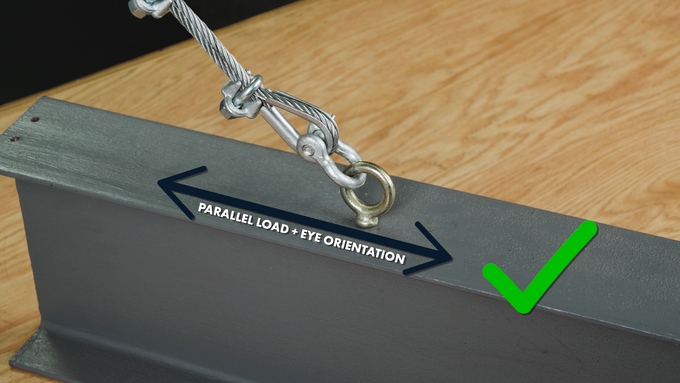

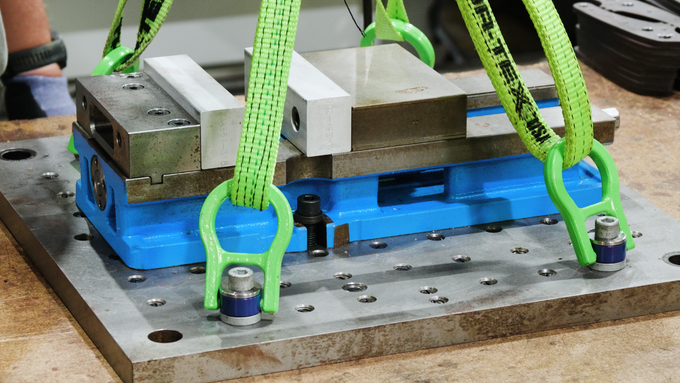

All eye bolts are designed for loading with the axis to the center of the eye. They should never be loaded perpendicular to that axis because they are likely to bend and break. So, when installing eye bolts for angular loading, make sure to align the eye of the bolt parallel with the lifting assembly.

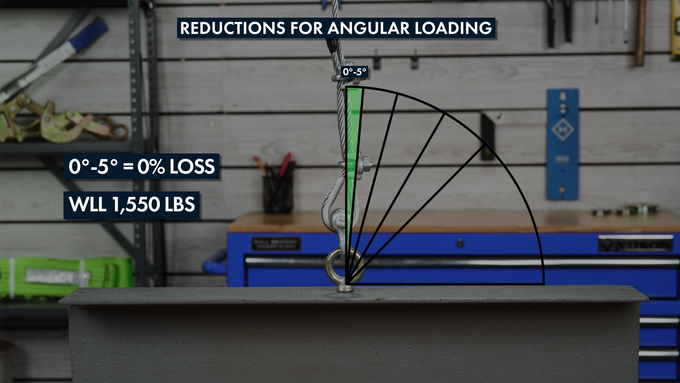

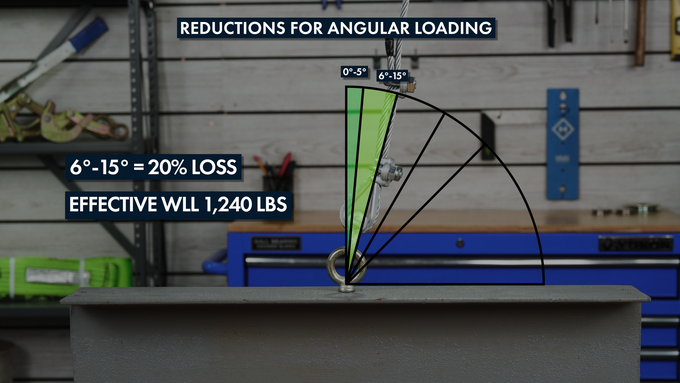

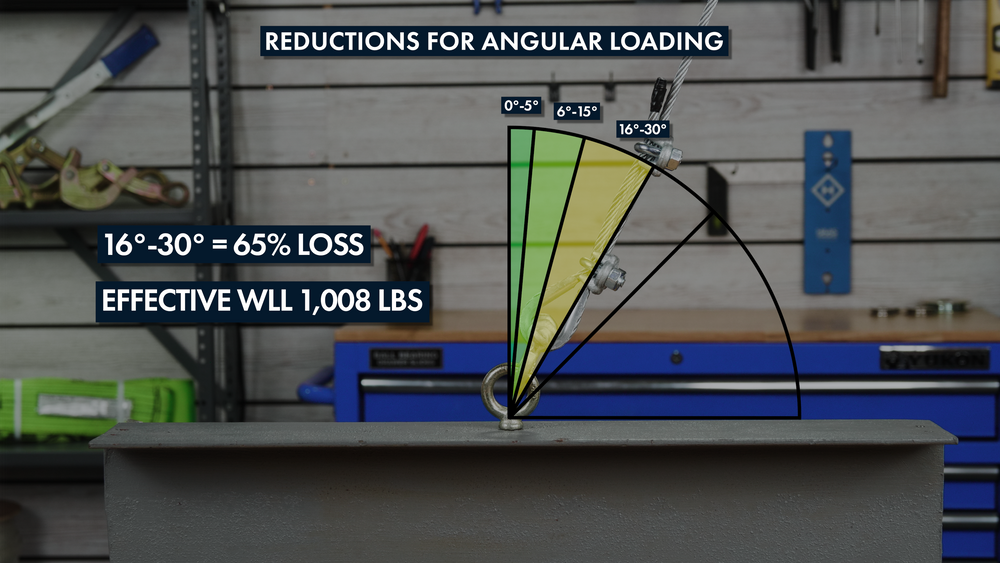

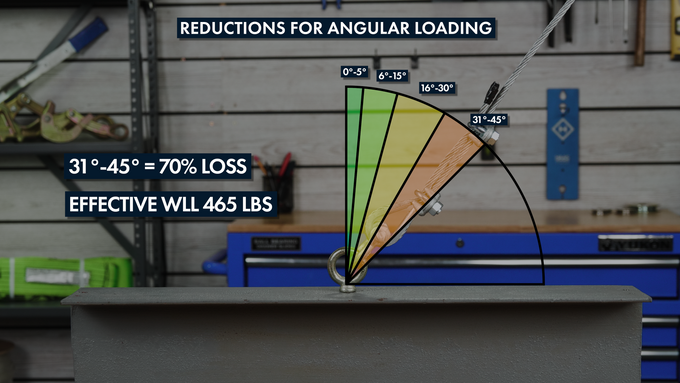

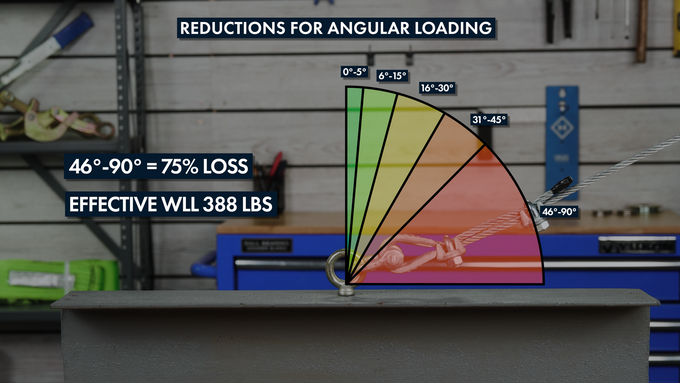

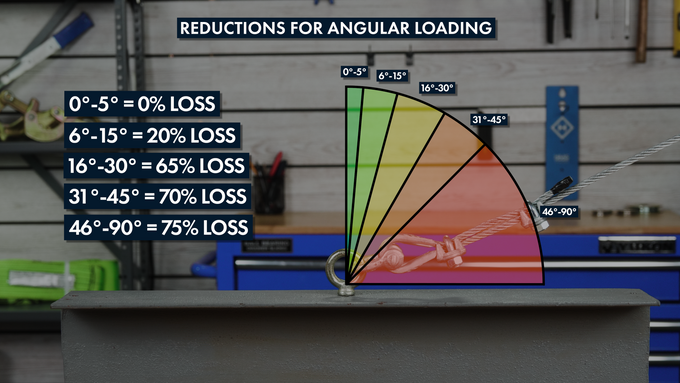

Angled Load Capacities for Shoulder and Machinery Eye Bolts

Shoulder or machinery eyebolts are a great option for angular lifting and suspension. However, it’s important to consider the angle of the lifting assembly since it will affect the working load limit of the eye bolt.

At 0 to 5 degrees, the eye bolt is rated at 100 percent of its working load limit. In this case, the catalog working load limit of this Pro Lift 3/8th inch eye bolt is 1,550 pounds.

At 6 to 15 degrees, the working load limit is reduced by 20% and the effective working load limit of the eye bolt becomes 1240 pounds, which is 80% of the original rated capacity.

16 to 30 degrees drops it to 65% of the original rated capacity.

31–45-degree angle of load reduces the working load limit by 70%.

90 degrees in the limit in which shoulder or machinery eye bolts are rated for load capacities, and results in a 75% reduction in working load capacity.

Taking angles into account and doing the math will help you avoid dangerous working conditions and assist you in completing safe successful lifts with shoulder and machinery eye bolts.

For higher profile, dynamic, and complex lifting jobs, we recommend considering swivel hoist rings as an alternative to eye bolts for angled loading, since they retain 100% of their working load limit through 180-degrees of pivot and 360-degrees of swivel. To read more about LFT Swivel Hoist Rings, click here.