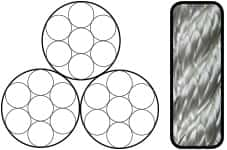

Twisted Rope

Laid rope, also called twisted rope, is historically the prevalent form of rope. Most twisted rope consists of three strands and is normally right-laid, or given a right-handed twist, with 2 and 4 strand ropes being constructed similarly. One of the drawbacks of this construction is that every fiber is exposed to abrasion numerous times along the length of the rope. This means that the rope can degrade to numerous inch-long fiber fragments, which is not easily detected visually. However, twisted rope is usually stronger than braided cord of the same size because its fibers are parallel to each other at all times.

E-Rigging.com has a large selection of 3-strand twisted rope in nylon, yellow polypropylene, and manila.

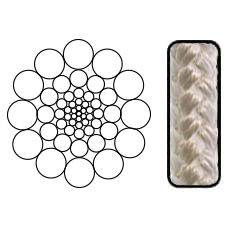

Solid Braided Rope

In solid braided rope, the strands all travel the same direction, clockwise or counter clockwise, and alternate between forming the outside of the rope and the interior of the rope. This construction is popular for general purpose utility rope but rare in specialized high performance line. As a locked stitch constructed rope with a smooth appearance and small vertical picks, it is extremely strong and cannot be unraveled, even when cut. It is one of the sturdiest types of rope, but cannot be spliced.

E-Rigging.com has a large selection of solid braided rope in nylon.

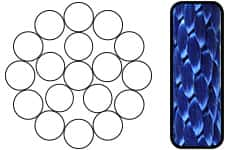

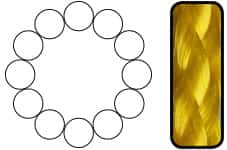

Hollow Braided Rope

Hollow braid rope is an easily spliced cord of a diamond braid construction; most common in nylon or polypropylene. Constructed of 8, 12 or 16 strands, hollow braided rope is the same as the diamond braided rope on the surface, but is coreless. Because it does not have a core, it makes it easy to splice. Hollow braided rope is braided into a circular pattern with half of the strands going clockwise and the other half going counter clockwise. The strands can interlock with either twill or plain weave.

E-Rigging.com has a large selection of polypropylene hollow braided rope.

| NYLON | POLYESTER | POLYPROPYLENE | MANILA | ||

|---|---|---|---|---|---|

| Physical Properties | |||||

| Strength | 5/5 Stars | 4/5 Stars | 3/5 Stars | 2/5 Stars | |

| Strength When Wet | -15% | No Change | No Change | +15% | |

| Shock Load Ability | 5/5 Stars | 3/5 Stars | 4/5 Stars | 2/5 Stars | |

| Elongation at Break | 20-34% | 15%-20% | 15%-20% | 10%-15% | |

| Flexing Endurance | 5/5 Stars | 4/5 Stars | 3/5 Stars | 2/5 Stars | |

| Specific Gravity | 1.14 | 1.38 | 0.9 | 1.38 | |

| Floats or Sinks in Water | Sinks | Sinks | Floats | Sinks | |

| Water Absorption | 6% | 0% | 0% | 100% | |

| Melting or Charring Point | Melts - 480° F | Melts - 500° F | Melts - 330° F | Chars - 350° F | |

| Storage Requirements | Wet or Dry | Wet or Dry | Wet or Dry | Dry Only | |

| Degradation Resistance | |||||

| Abrasion | 4/5 Stars | 5/5 Stars | 2/5 Stars | 3/5 Stars | |

| Sunlight / UV | 3/5 Stars | 5/5 Stars | 1/5 Stars | 3/5 Stars | |

| Rot | 5/5 Stars | 5/5 Stars | 5/5 Stars | 1/5 Stars | |

| Acids | 1/5 Stars | 3/5 Stars | 3/5 Stars | 1/5 Stars | |

| Alkalies | 3/5 Stars | 1/5 Stars | 3/5 Stars | 1/5 Stars | |

| Oil, Gas, & Petroleum Based Liquids | 3/5 Stars | 3/5 Stars | 3/5 Stars | 1/5 Stars | |

| Electrical Conductivity Resistance | 1/5 Stars | 3/5 Stars | 3/5 Stars | 1/5 Stars | |

| Best =5/5 Stars | Worst =1/5 Stars | |||||

Visit our Rope collection to view

Back to top