Rope (Soft Rope/Fiber Rope)

Use our Rope Strength Guide, Rope Fiber Guide, Rope Construction Guide, Rope Comparison Chart, and Rope Tolerance Guide to choose the right rope for your needs.

For all your industrial and marine rope needs, look no further. E-Rigging.com has the most common types of marine and industrial ropes in a variety of sizes up to – and including – bulk reels of 1200 feet. We specialize in providing all types of rope and rope accessories including twisted nylon rope, polypropylene rope, manila rope, and several other options in any size. If you have any questions or inquiries about our soft rope or rope accessories, please feel free to contact our sales team. We look forward to helping you find the perfect solution for your next job!

| NYLON | POLYESTER | POLYPROPYLENE | MANILA | ||

|---|---|---|---|---|---|

| Physical Properties | |||||

| Strength | 5/5 Stars | 4/5 Stars | 3/5 Stars | 2/5 Stars | |

| Strength When Wet | -15% | No Change | No Change | +15% | |

| Shock Load Ability | 5/5 Stars | 3/5 Stars | 4/5 Stars | 2/5 Stars | |

| Elongation at Break | 20-34% | 15%-20% | 15%-20% | 10%-15% | |

| Flexing Endurance | 5/5 Stars | 4/5 Stars | 3/5 Stars | 2/5 Stars | |

| Specific Gravity | 1.14 | 1.38 | 0.9 | 1.38 | |

| Floats or Sinks in Water | Sinks | Sinks | Floats | Sinks | |

| Water Absorption | 6% | 0% | 0% | 100% | |

| Melting or Charring Point | Melts - 480° F | Melts - 500° F | Melts - 330° F | Chars - 350° F | |

| Storage Requirements | Wet or Dry | Wet or Dry | Wet or Dry | Dry Only | |

| Degradation Resistance | |||||

| Abrasion | 4/5 Stars | 5/5 Stars | 2/5 Stars | 3/5 Stars | |

| Sunlight / UV | 3/5 Stars | 5/5 Stars | 1/5 Stars | 3/5 Stars | |

| Rot | 5/5 Stars | 5/5 Stars | 5/5 Stars | 1/5 Stars | |

| Acids | 1/5 Stars | 3/5 Stars | 3/5 Stars | 1/5 Stars | |

| Alkalies | 3/5 Stars | 1/5 Stars | 3/5 Stars | 1/5 Stars | |

| Oil, Gas, & Petroleum Based Liquids | 3/5 Stars | 3/5 Stars | 3/5 Stars | 1/5 Stars | |

| Electrical Conductivity Resistance | 1/5 Stars | 3/5 Stars | 3/5 Stars | 1/5 Stars | |

| Best =5/5 Stars | Worst =1/5 Stars | |||||

Manila Rope

Manila rope was once the preferred choice in ropes before synthetic fibers were developed. Manila ropes still maintain some advantages to synthetic fibers. It is not affected by heat, and has an excellent resistance to the sun's UV (Ultraviolet) rays. Manila rope has low stretch and good abrasion resistance, but poor chemical resistance, subject to rot.

E-Rigging.com has a large selection of 3-Strand Twisted Manila Rope in lengths up to and including 1200 feet.

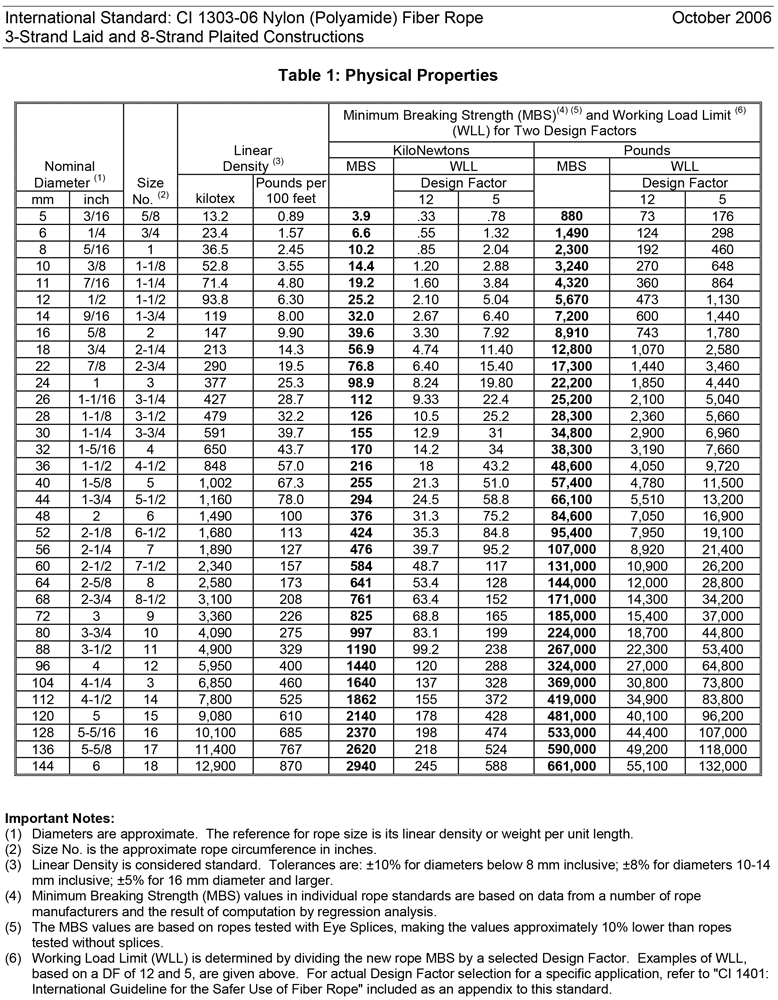

Nylon Rope

Nylon Rope is known for its elasticity and tremendous shock absorbing qualities. It has good abrasion resistance, is rot proof, resists oil, gasoline, and most chemicals. It has good resistance to UV rays. Nylon will last 4-5 times longer than natural fibers.

E-Rigging.com has a large selection of 3-Strand Twisted Nylon Rope, Solid Braid Nylon Rope, and Double Braided Nylon Rope in lengths up to and including 1000 feet.

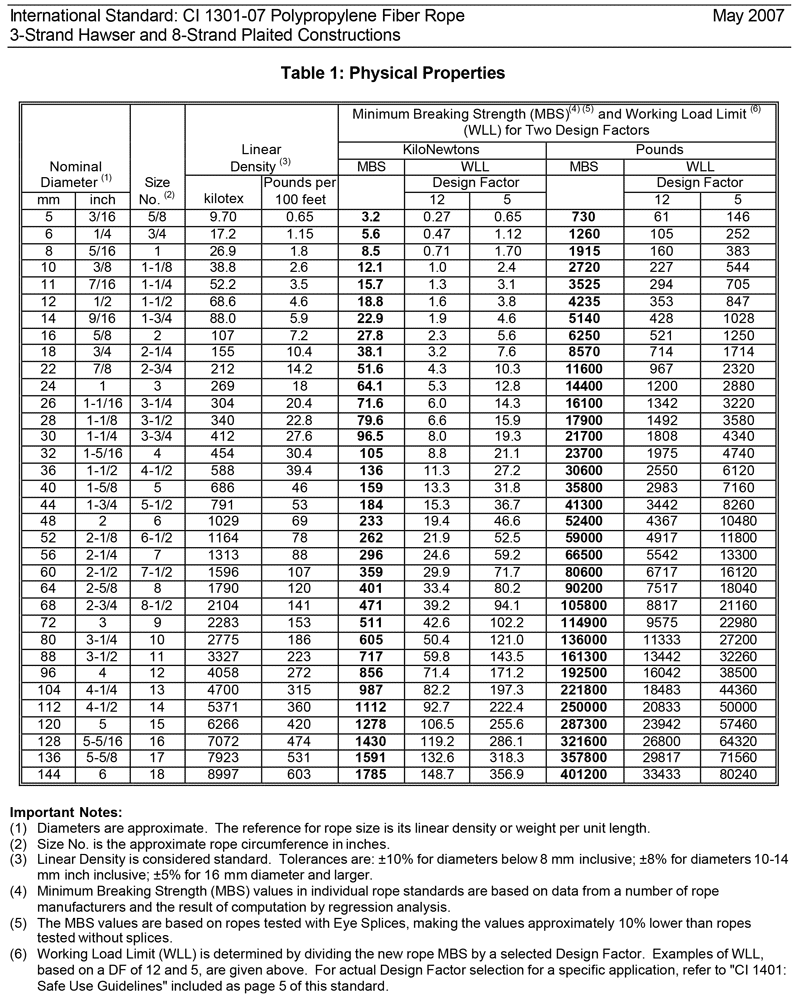

Polypropylene Rope

Polypropylene rope will float, has excellent resistance to most common chemicals. It is also resistant to rot, mildew and deterioration. It has good abrasion resistance, good strength, and moderate stretch. It is a perfect economical choice as a general purpose rope.

E-Rigging.com has a large selection of 3-Strand Twisted Yellow Polypropylene Rope and Hollow Braid Polypropylene Rope in lengths up to and including 600 feet.

Polyester Rope

Polyester rope is high strength, low stretch, torque free, excellent wet/dry abrasion resistant and wet/dry strength. Good resistance to ultraviolet rays and common chemicals. Obtains the best weathering characteristics of all popular fibers. Polyester stretches less than nylon, so it does not have the elasticity of shock absorbing qualities that nylon does. It is very popular as a marine or industrial rope where stretch is not desired.

E-Rigging.com has a selection of Double Braided Polyester Rope in lengths up to and including 600 feet.

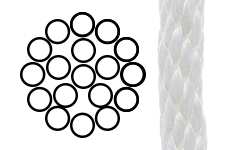

Twisted Rope

Laid rope, also called twisted rope, is historically the prevalent form of rope. Most twisted rope consists of three strands and is normally right-laid, or given a right-handed twist, with 2 and 4 strand ropes being constructed similarly. One of the drawbacks of this construction is that every fiber is exposed to abrasion numerous times along the length of the rope. This means that the rope can degrade to numerous inch-long fiber fragments, which is not easily detected visually. However, twisted rope is usually stronger than braided cord of the same size because its fibers are parallel to each other at all times.

E-Rigging.com has a large selection of 3-strand twisted rope in nylon, yellow polypropylene, and manila.

Solid Braided Rope

In solid braided rope, the strands all travel the same direction, clockwise or counter clockwise, and alternate between forming the outside of the rope and the interior of the rope. This construction is popular for general purpose utility rope but rare in specialized high performance line. As a locked stitch constructed rope with a smooth appearance and small vertical picks, it is extremely strong and cannot be unraveled, even when cut. It is one of the sturdiest types of rope, but cannot be spliced.

E-Rigging.com has a large selection of solid braided rope in nylon.

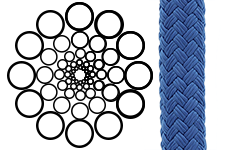

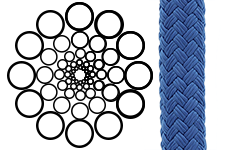

Hollow Braided Rope

Hollow braid rope is an easily spliced cord of a diamond braid construction; most common in nylon or polypropylene. Constructed of 8, 12 or 16 strands, hollow braided rope is the same as the diamond braided rope on the surface, but is coreless. Because it does not have a core, it makes it easy to splice. Hollow braided rope is braided into a circular pattern with half of the strands going clockwise and the other half going counter clockwise. The strands can interlock with either twill or plain weave.

E-Rigging.com has a large selection of polypropylene hollow braided rope.

Tolerances are: ±10% for diameters below 5/16 inches (8 mm) inclusive; ±8% for diameters 3/8 – 9/16 inches (10-14 mm) inclusive; ±5% for 5/8 inches (16 mm) diameter and larger.

For Example:

- 1/4" rope can be .225" to .275" in diameter and still be within tolerance.

- 1/2" rope can be .46" to .54" in diameter and still be within tolerance.

NOTE: These are the listed Breaking Strengths of each rope type and size. It is recommended not to exceed 1/3 (3:1 Design Factor) of the rope's strength to maintain a useful service life.

Back to top